Profile

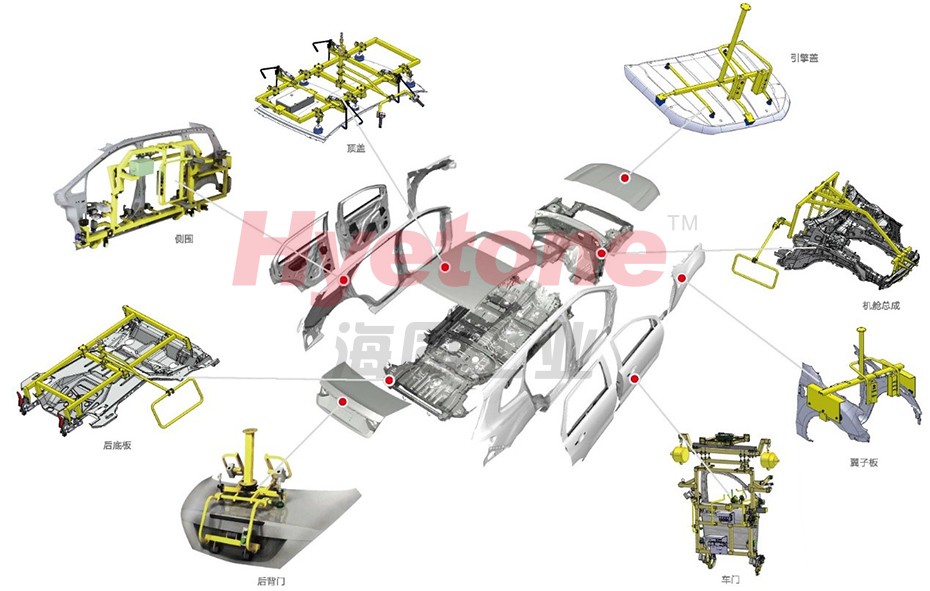

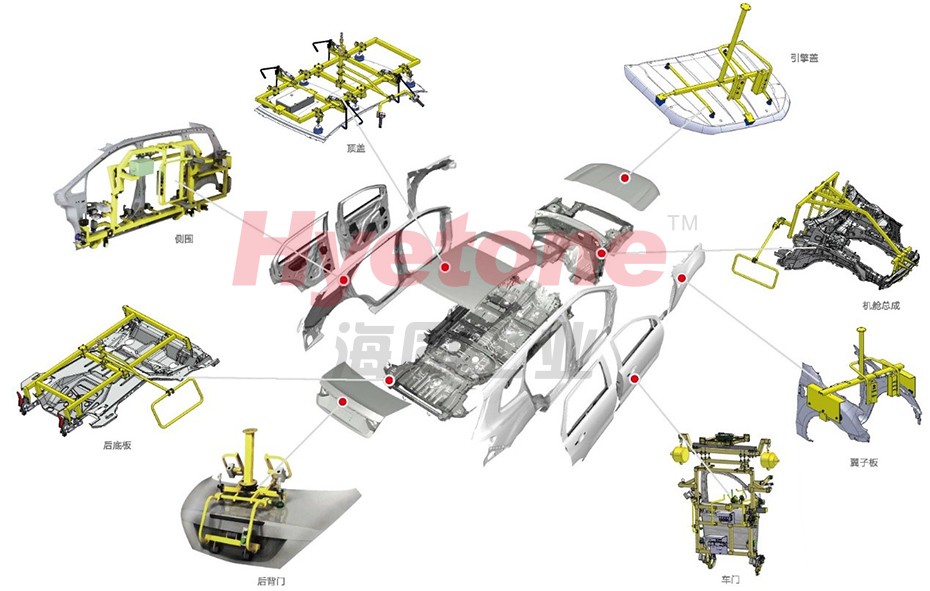

一汽-大众汽车有限公司是由中国第一汽车集团公司和德国大众汽车股份公司、奥迪汽车股份公司及大众汽车(中国)投资有限公司合资经营的大型轿车生产企业,是我国第一个按经济规模起步建设的现代化轿车工业基地。 一汽-大众汽车有限公司采用先进技术和设备制造当今世界名牌产品-捷达、宝来、高尔夫、开迪、奥迪系列轿车。它的建成,使我国轿车工业进入了大规模生产的新时期。国家对外经济贸易部确认一汽-大众为“技术先进企业”,国家统计局授予一汽-大众为“中国汽车制造名优企业”,国家机械局授予一汽-大众为“在促进科学技术进步工作中做出重大贡献者”一等奖。

FAW-Volkswagen Automobile Co., Ltd. is a large-scale car production enterprise jointly operated by China First Automobile Group Corporation, Volkswagen AG, Audi AG and Volkswagen (China) Investment Co., Ltd. and it is the first modernized car industrial base in China which was built according to the economic scale from the beginning. FAW-Volkswagen adopts advanced technology and equipment to manufacture the world famous brand products - Jetta, Bora, Golf, Kaidi and Audi series cars. Its completion has enabled China's car industry to enter a new period of mass production. The Ministry of Foreign Economic Relations and Trade recognized FAW-Volkswagen as a "technologically advanced enterprise", the National Bureau of Statistics awarded FAW-Volkswagen as a "Famous and Excellent Enterprise of China's Automobile Manufacturing", and the National Machinery Bureau awarded FAW-Volkswagen as an "Enterprise that has made great contributions to the promotion of scientific and technological progress". The State Bureau of Machinery honored FAW-Volkswagen with the first prize of "Significant Contributors in Promoting Scientific and Technological Progress".

Difficulties

一汽一汽大众是公认一流的智能汽车工业设备的设计和制造企业,非常注重生产车间人因功效和工作场所高效人机交互匹配及环境改善。于是找到了海同工业希望为他们解决焊装车间调整线环境作业设备改善等问题。

一汽大众焊装车间调整线原设备状态为:

FAW FAW-Volkswagen is recognized as a first-class designer and manufacturer of intelligent automotive industrial equipment, and pays great attention to the human factors efficacy of production workshops and efficient human-machine interaction matching and environment improvement in the workplace. So they found HITECH to solve the problem of improving the environment of welding workshop adjustment line for them.

The original equipment status of FAW-Volkswagen's welding workshop adjustment line is as follows:

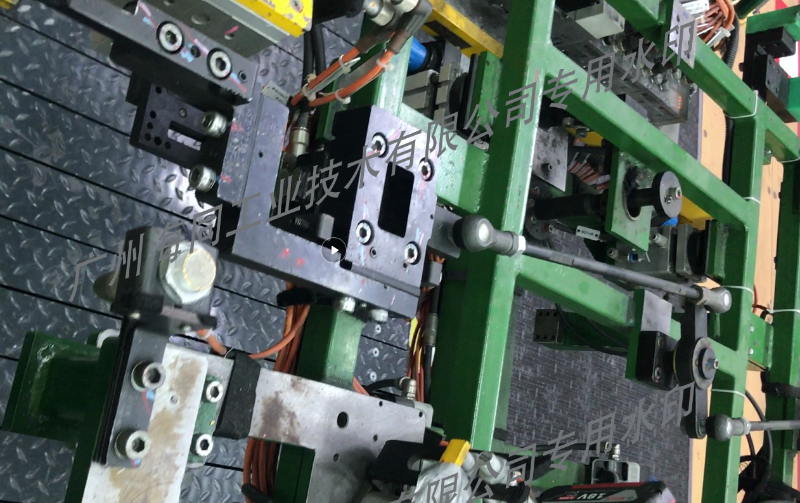

1、前盖闭合装具拧紧螺母为左右各一,人工开盖后,持枪拧紧剩余螺母左右各一,操作繁琐,花费工时长;工人在作业工序中存在较多不良姿势,作业效率有较大空间可以提升。

2、前盖装具与提升主机水平托架现场为分层设计,且为浮动连接,装具上精导向销与车身减震孔X和Y向定位, 装具上气缸与车身前纵梁Z向夹紧.白车身随板带前进时,车身推动装具,装具推动提升主机水平托架,使提升主机X向轨道移动.现场装具倾斜严重,对装具精度有影响,花费较多调整工时;

3、提升主机扶手现长反馈操作时,容易断裂,安全隐患大,影响正常生产。

1, the front cover closure fixture tightening nuts for the left and right one, manual open the cover, holding the gun to tighten the remaining nuts left and right one, the operation is cumbersome, spend a long time; workers in the operation process there are more bad posture, operational efficiency has a large space can be improved.

2, the front cover fixture and lifting the host level bracket site for the layered design, and for the floating connection, fixture on the fine guide pin and the body shock absorbing holes X and Y direction positioning, fixture on the cylinder and the front longitudinal beam of the body Z direction clamping. When the white body advances with the belt, the body pushes the fixture, and the fixture pushes the horizontal bracket of the lifting main body, so that the lifting main body moves to the rail in X direction. The fixtures on site are tilted seriously, which affects the accuracy of the fixtures and costs more adjustment time;

3, lifting the host handrail is now long feedback operation, easy to break, safety hazards, affecting normal production.

Needs Programs

客户期望海同工业可以提供解决方案: 改善人机工程环境,使现场工作条件适应产线及人的需要,达到生产节拍52秒的高频率高精度作业,并充分减少工人的工作劳动强度,达到很好的一致性性能。

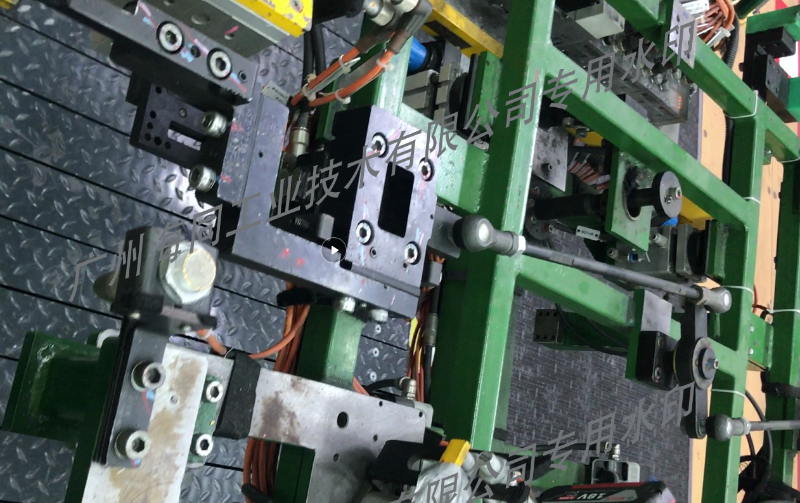

结论:海同工业技术工程师经过现场测绘及考察认为,通过结构更加优化的AMB前盖闭合打紧“人因工程装具”可有效改善焊装车间调整线作业环境、设备改善等问题,达到增加装配精度、节省作业时间,调整设备以适应人的工作。

1、 人工开盖后,可直接取出装具,进行下一循环,减少人工打钉的劳动强度。改善原工序中的不良姿势,减少WMSDs风险。

2、前盖装具与提升主机水平托架结构优化,装具不受提升主机影响。安装精度显著提升;设置恰当的设备操作高度,及按钮力度,工人操作起来更加舒适便捷,且设备高度、角度可调,适应不同工人操作需要。

3、装具扶手采用整体圆管折弯制作,并增加加强筋,满足使用强度,提高装具整体安全性、稳定性。扶手上采用人机工程按钮。全面考虑人机工程解决方案,将工作范围锁定在身体正前方及肘关节上下几英寸的舒适区内。

The customer expects Hyetone Industry to provide the solution: Improve the ergonomic environment, adapt the working conditions to the production line and the needs of people, achieve the production beat of 52 seconds of high-frequency high-precision work, and fully reduce the labor intensity of workers, to achieve good consistency performance.

Conclusion: The technical engineers of Hai Tong Industry, after on-site mapping and inspection, believe that the more optimized AMB front cover closing and tightening "Human Factors Engineering Fixture" can effectively improve the operating environment of the adjustment line in the welding workshop, improve the equipment and other issues, so as to achieve the increase in assembly precision, save operating time, and adjust the equipment to adapt to the work of the human being.

1、 After opening the cover, the fixture can be taken out directly for the next cycle, reducing the labor intensity of manual nailing. Improve the bad posture in the original process and reduce the risk of WMSDs.

2、The structure of the front cover fixture and the horizontal bracket of the lifting host is optimized, and the fixture is not affected by the lifting host. Installation accuracy is significantly improved; set the appropriate operating height of the equipment and button strength, workers operate more comfortable and convenient, and the height and angle of the equipment can be adjusted to adapt to the needs of different workers to operate.

3、The handrail of the fixture is made by bending the whole round tube and increasing the reinforcement to meet the intensity of use and improve the overall safety and stability of the fixture. The handrail adopts ergonomic buttons. Comprehensive consideration of ergonomic solutions to lock the working range in front of the body and a few inches above and below the elbow joint within the comfort zone.

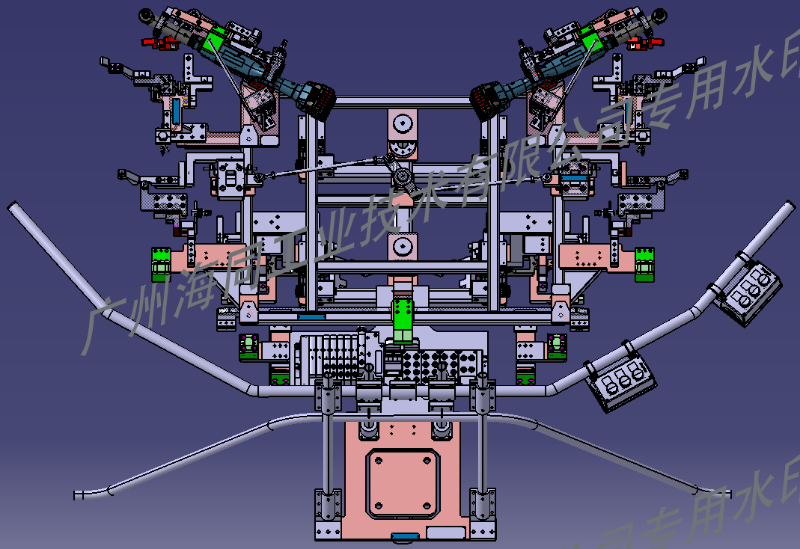

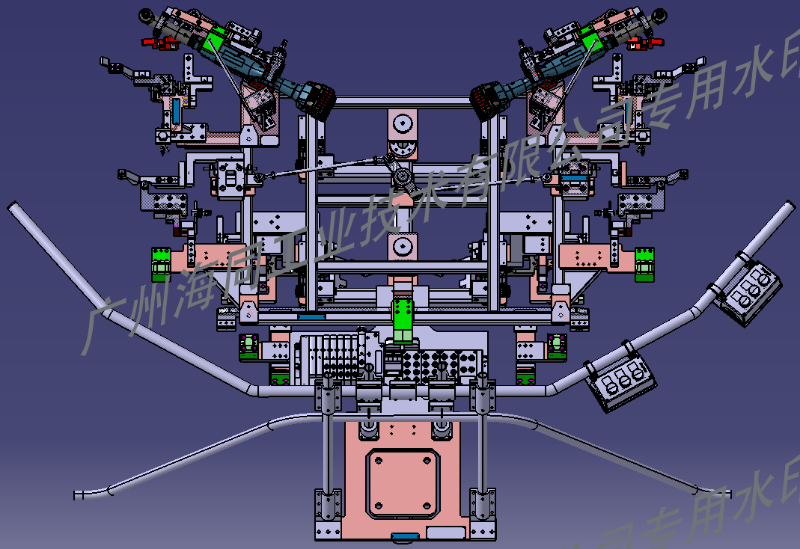

图 1:AMB前盖闭合自动打紧“人因工程装具”AMB-FHD

Fig. 1: AMB Front Cover Closing Automatic Tightening "Ergonomic Fixture" AMB-FHD

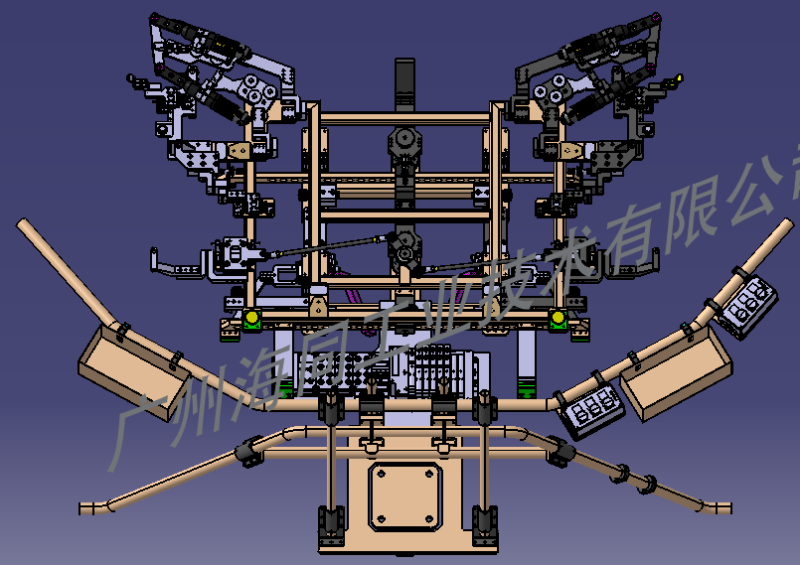

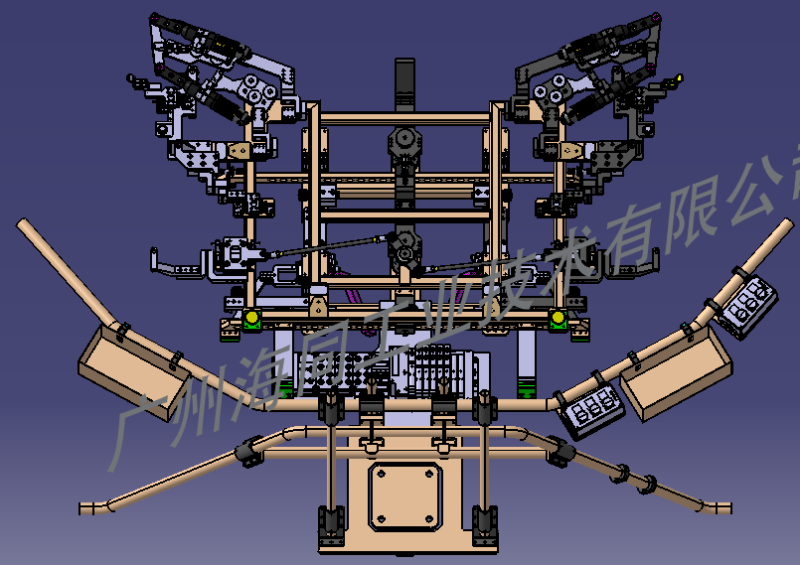

图2 :AMB前盖闭合自动打紧“人因工程装具”AMB-FHD2

Fig. 2 : AMB Front Cover Closing Auto Tightening "Ergonomic Fixture" AMB-FHD2