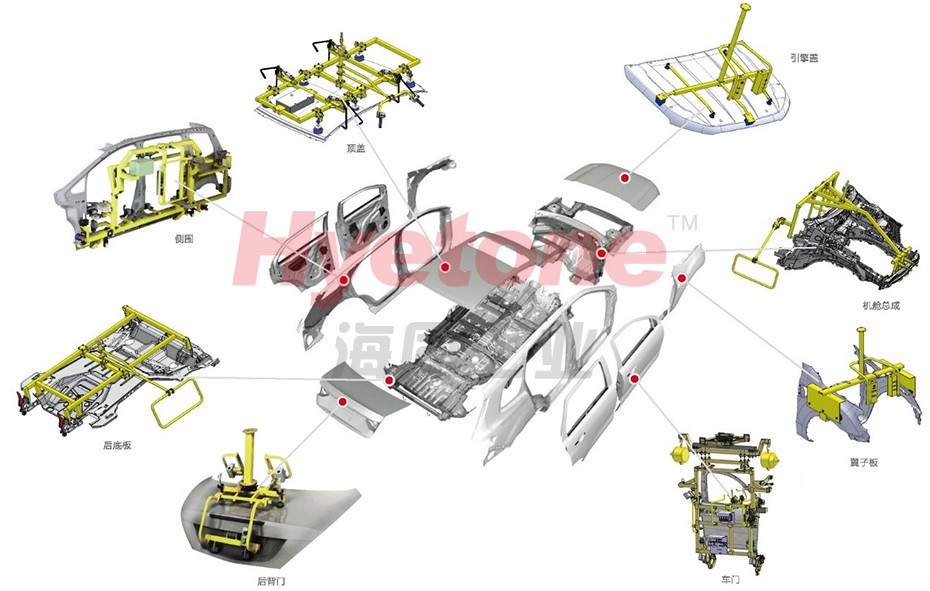

焊装调整线是白车身整车下线前的最后一道工序,是保证白车身各装配部件的间隙、面差、段差精度及装配一致性的重要环节。其工艺装备主要包括装配夹具、装配辅具、检具、工具及输送系统等。其中工具属于标准化工具,输送系统相对固定的模式,只要能满足生产纲领即可,其结构具有一定的通用性,柔性化程度高;只有装配夹具、装配辅具是用来保证四门两盖与车身的刚性连接,控制车身总成与各连接部位的间隙、面差、段差精度及装配一致性的。因此装配夹具、装配辅具的设计理念、设计基础、设计结构、设备调试与应用推广将直接影响整车的装配质量。

Welding adjustment line is the last process before the body-in-white vehicle comes off the production line, and it is an important link to ensure the gap, surface difference, segment difference precision and assembly consistency of each assembly part of the body-in-white. Its process equipment mainly includes assembly fixture, assembly auxiliary, inspection, tools and conveyor system. Among them, the tools belong to standardized tools, conveyor system is relatively fixed mode, as long as it can meet the production program, its structure has a certain degree of universality, high degree of flexibility; only assembly fixture, assembly aids are used to ensure that the four doors and two covers and the body of the rigid connection, control the body assembly and the connection parts of the gap, surface difference, segment difference accuracy and assembly consistency. Therefore, the design concept, design basis, design structure, equipment debugging and application promotion of assembly jigs and fixtures will directly affect the assembly quality of the whole vehicle.

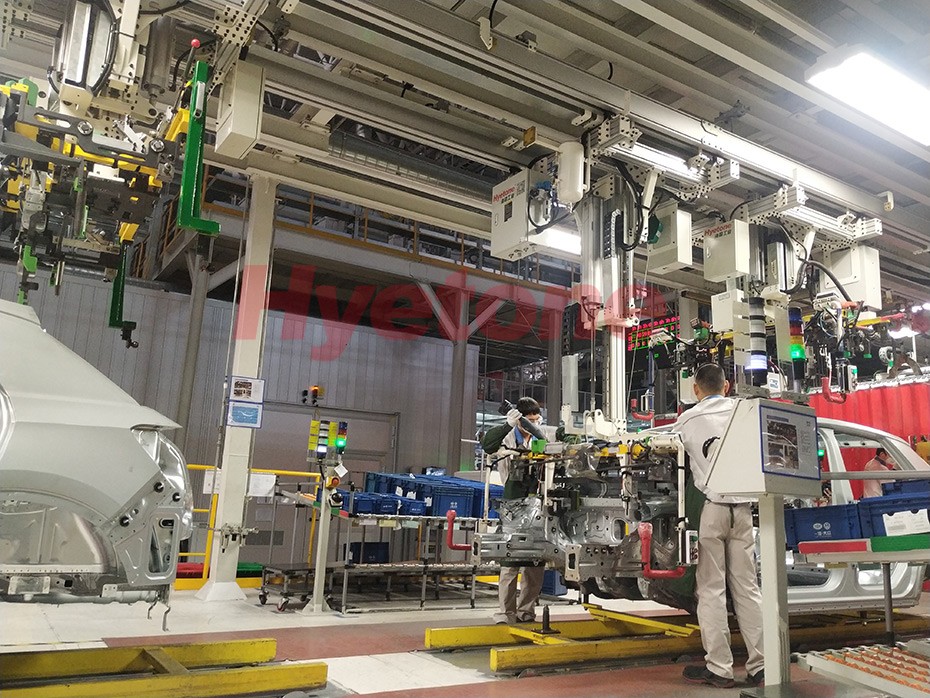

国内目前主流汽车厂调整线现场,我们可以看到其焊装车间调整线一直采用普通的简单装具,工人都是手持简易工装手动打紧进行作业,造成整车一致性效果差,后续还需要大量的人工去调整修模,增加劳动强度,且工作量大,对生产节拍产生很大影响,无法长期进行生产。但因技术原因,之前一直采用多班轮换来解决此问题。

汽车调整线生产现场环环巷口,讲究的是生产节拍和效率,如何打造高效又省力的人机交互助力装具是海同生产线复杂装具设计的主题,海同工业通过现场实地考察及预工作人员深入探讨,设计高度定制化装具并充分考虑人机结合适应性。

The production site of automobile adjusting line is surrounded by alleys, which is concerned about the production rhythm and efficiency, how to create efficient and labor-saving man-machine interaction assisted fixtures is the theme of complex fixture design of Hai Tong production line, Hai Tong Industry through the on-site field visits and in-depth discussions with the staff, designing highly customized fixtures and giving full consideration to the adaptability of the combination of man-machine.

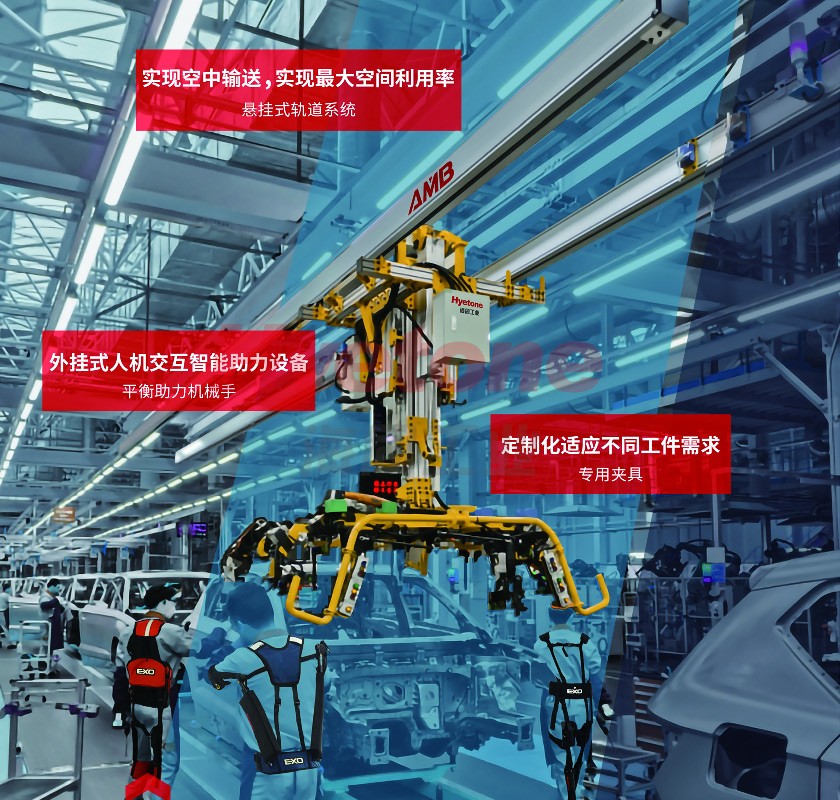

海同工业可通过更改原有的装配工艺,实现自动打紧,改善产品打紧后一致性不稳定等问题来增加装配精度及节省时间。经过验证讨论,采用海同工业提供的人机交互助力设备与车身复杂工装相结合达到生产节拍57秒的高频率该精度作业,并充分减少工人的工作劳动强度,并达到优良的一致性性能。

By changing the original assembly process, Hyetone can realize automatic tightening and improve the unstable consistency of the product after tightening to increase the assembly precision and save time. After verification and discussion, the human-machine interaction equipment provided by Hai Tong Industry combined with the complex bodywork to achieve a production beat of 57 seconds of high-frequency precision work, and fully reduce the labor intensity of the workers, and achieve excellent consistency performance.

车间工人在移动过程中,工装助力机械手覆盖不到的位置,工人可通过穿戴的人机协作外骨骼,达到特定工位助力保护的效果。减少身体负担,从而提供工作效率。

通过外挂式焊装调整线柔性装配工具及穿戴式外骨骼,多方位给劳动者赋能,解决工人由于长期高负荷作业,需要频繁换岗,并保护工人不受职业健康劳动损伤风险。

海同工业目前已获得10项调整线复杂装具相关专利,专利技术在汽车四门两盖自动调整线装配生产过程中解决了技术领域关键共性问题,使产品形成系列化、标准化,并从整体上提升了产品的技术水平。

AMB-Hop-line tool焊装调整线柔性装配工具包含:AMB-E系列空中输送铝合金轨道系统 、AMB-T系列平衡主机、AMB-F系列装具夹具、AMB-A系列辅助检具及型面样板、AMB-H系列装配辅助移载吊具。柔性装配工具能发挥装配工具的最大性能潜力,实现产线的价值增长,是保证白车身各装配部件的间隙、面差、段差精度及装配一致性的重要工具。

AMB-Hop-line tool includes: AMB-E series of aluminum alloy rail system for air conveyor, AMB-T series of balancing machine, AMB-F series of fixtures, AMB-A series of auxiliary inspectors and pattern samples, and AMB-H series of auxiliary lifting tools for assembly. Flexible assembly tools can give full play to the maximum performance potential of the assembly tools and realize the value growth of the production line, which is an important tool to ensure the gap, surface difference, segment difference precision and assembly consistency of each assembly part of the body-in-white.