步入2022年,在我国的新能源锂电池产业链快速发展情况的带动下,市场逐渐形成了对铝塑膜、等极片等卷料 的需求量急速激增。 而照目前来看, 新能源卷料 行业仍然存在着不少的问题/隐患,那么主要存在哪一些问题呢?

Step into 2022, in China's new energy lithium battery industry chain under the drive of the rapid development of the situation, the market has gradually formed a rapid surge in demand for aluminum-plastic film, such as pole pieces and other roll materials. But according to the current point of view, the new energy coil industry still exists a lot of problems / hidden dangers, so what are the main problems?

1、安全隐患

在以铝塑膜为代表的卷料产品的生产过程中,一般需要在工位之间把卷料进行反复搬运,特别是在电池生产的过程中,需要将金属卷料在预分切之后进行分切,即需要将金属卷料从预分切工位搬运到分切工位上,物料在不同工序转运,人工接触风险较高 。传统搬运过程中容易出现卷料掉落的情况,物流通道狭窄,人机混行都有安全隐患。

1、Safety Hazards

In the production process of rolled products represented by aluminum-plastic film, it is generally necessary to carry the rolled materials repeatedly between the stations, especially in the process of battery production, it is necessary to slit the metal rolled materials after pre-slitting, i.e., it is necessary to carry the metal rolled materials from the pre-slitting station to the slitting station, and the materials are transported in different processes, and the risk of artificial contact is high. Conventional handling process is prone to drop the coil material, narrow logistics channel, human-machine mixing are all safety hazards.

2、产能待优化

随着新能源车的普及,动力电池行业规模预计将快速增长。2020年全球动力电池装机量为 139GWH, SNE Research预测全球动力电池装机量在 2025年将达到940GWH, 2020-2025 年复合增速超过45%。提升电池产能日益迫切,;

2、Capacity to be optimized

With the popularization of new energy vehicles, the scale of power battery industry is expected to grow rapidly. 2020 global power battery installed capacity is 139GWH, SNE Research predicts that the global power battery installed capacity will reach 940GWH in 2025, with a compound growth rate of more than 45% in 2020-2025. It is increasingly urgent to improve battery production capacity;

3、物料管理

各工序之间缓存物料多,没有实时库存数据,需要人工定期盘点;仓库按照ERP计划批量出库,与产线需求有差异,造成缓存区爆库;线边缓存架位置分散,没有上下架指示,造成产线与所需物料距离较远。

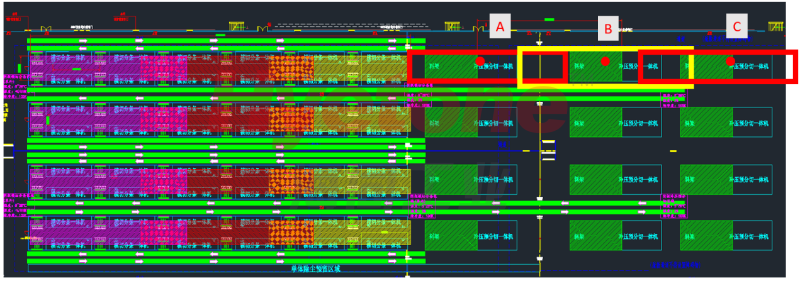

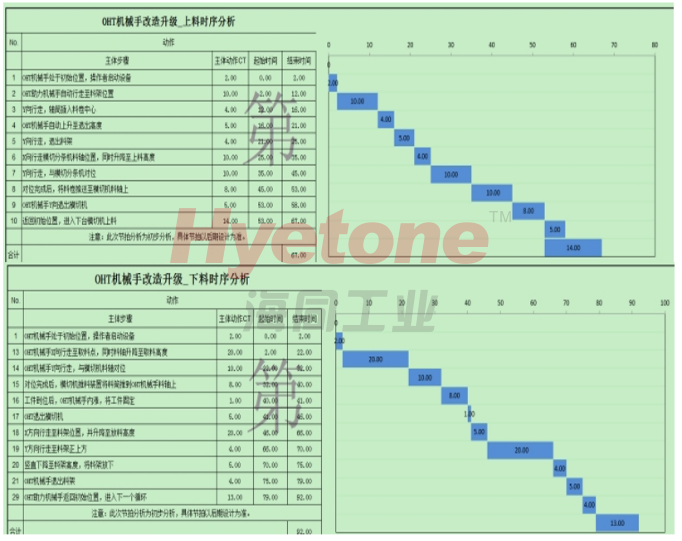

针对此,海同工业AMB产品线设计的OHT机械手改造升级自动上下料- EHS人机交互 数字化解决方案,可通过人机交互智能集成系统打造这类解决方案。

3、Material Management

There are a lot of cached materials between each process, no real-time inventory data, need to manually inventory on a regular basis; the warehouse according to the ERP plan batch out of the warehouse, and the difference between the production line demand, resulting in the cache area of the burst warehouse; the location of the line-side cache shelves are scattered, there is no up and down shelves instructions, resulting in the production line and the required materials are far away from each other.

In response to this, Hai Tong Industrial's AMB product line has designed the OHT robot retrofit to upgrade the automatic loading and unloading - EHS HMI digital solution, which can create this kind of solution through the HMI intelligent integration system.

相对传统葫芦等助力提升设备应用,EHS-OHT自动上下料系统能极大改善以下几点:

Compared to traditional hoist and other power-assisted lifting equipment applications, the EHS-OHT automatic loading and unloading system can greatly improve the following points:

(1)、 负载能力提升

市面主流智能葫芦最大提升负载均在600Kg内,负载提升能力受限,如在新能源行业,部分电极卷料重量约800Kg,采用智能葫芦不能实现负载需求,而EHS-OHT自动上下料系统,具有高刚性导向,可有效抵抗偏载力矩,上下料精准对位。

(1) Load capacity increase

Mainstream intelligent hoists in the market have a maximum lifting load of 600Kg, which limits the load lifting capacity. For example, in the new energy industry, the weight of some of the electrode coils is about 800Kg, and the intelligent hoists can not realize the load demand, while the EHS-OHT automatic loading and unloading system has a high rigidity guide, which effectively resists the off-loading moment, and the loading and unloading can be accurately aligned.

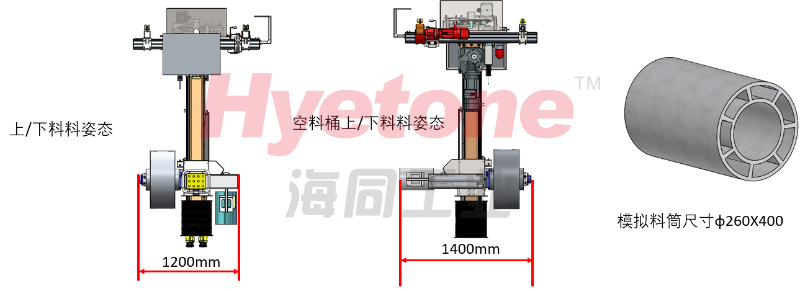

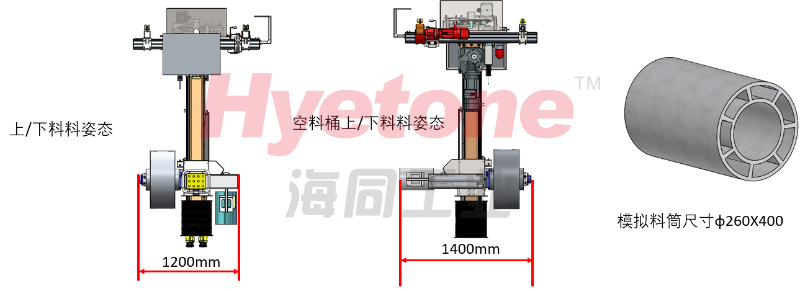

(2)、 更大提升行程

相对常规轨道式柔性提升智能葫芦,设备本体占用空间大,采用EHS-OHT自动上下料系统,同等厂房高度工况,OHT提升行程比更大,能最大化满足分切机 台高位卷料的上料与下料作业(例:厂房高度3450mm,上料设备高度2850mm,最高位卷料对接高度1680mm,则常规智能软索葫芦吊不能实现,配置EHS-OHT机械手自动上下料系统能轻松实现)。

(2), larger lifting stroke

Relative to the conventional rail-type flexible lifting intelligent hoist, the equipment body occupies a large space, the use of EHS-OHT automatic loading and unloading system, the same plant height conditions, the OHT lifting stroke than the larger, can maximize to meet the slitting machine table high level of the coil material loading and unloading operations (Example: the plant height of 3450mm, the loading equipment height of 2850mm, the highest level of the coil material docking height of 1680mm, it can not be achieved, configure EHS-OHT robotic automatic loading and unloading system can easily achieve). Conventional intelligent soft rope hoist can not be realized, the configuration of EHS-OHT robot automatic loading and unloading system can be easily realized).

(3)、更大覆盖范围

采用EHS-OHT自动上下料系统,能满足多台分切机台上下料,兼容下空桶功能,一台机常规可覆盖20米范围,满足两侧对称布置分切机上下料,极大提升设备利用率、空间布局更优化合理。

(3) Greater coverage

Adopting EHS-OHT automatic loading and unloading system, it can meet the feeding of multiple slitting machines on the table, compatible with the function of empty drums, and a machine can routinely cover a range of 20 meters to meet the symmetrical arrangement of slitting machine loading and unloading on both sides, which can greatly improve the utilization rate of the equipment and optimize the space layout.

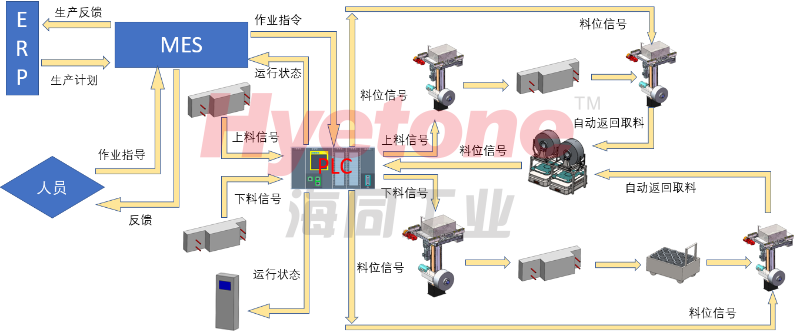

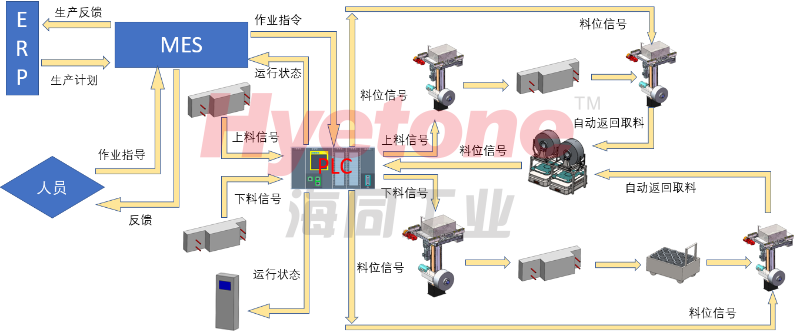

(4)、系统扩展性强

相对智能提升葫芦,EHS-OHT自动上下料系统能无限软件与硬件扩展,系统化人机工作站,可集成ERP、MRP、MES、LES、WMS、TMS等多项物料生产管理系统,实现数字化精益生产。

(4) Strong system expandability

Relative to the intelligent lifting hoist, EHS-OHT automatic loading and unloading system can be unlimited software and hardware expansion, systematic man-machine workstations, can be integrated with a number of material production management systems such as ERP, MRP, MES, LES, WMS, TMS, and so on, to achieve digital lean production.

(5)、EHS轻劳化作业

常规葫芦提升配置轨道系统,操作工均需要手动水平推动、上下按钮对位及上下料,单台设备上下料时间在2min,常规600Kg级提升设备负载状态,手动推动操作力在6Kgf以上,单班8小时长时间作业,持续劳动强度大,易产生WMSDs肌肉筋骨劳损 work-related musculoskeletal disorders。在人工上下料传统工位,员工工作一天下来非常累,人员流失非常严重,人力成本激增, EHS-OHT自动上下料系统采用数字化交互界面,工作变得更容易,更轻松智能,生产效率也有了很大的提升。

(5), EHS light labor operation

Conventional hoist lifting configuration track system, operators need to manually push the horizontal, up and down button alignment and loading and unloading, a single piece of equipment loading and unloading time in 2min, conventional 600Kg level lifting equipment load state, manually push the operating force in the 6Kgf or more, a single shift of 8 hours of prolonged operation, continuous labor intensity, easy to produce WMSDs work-related musculoskeletal disorders. work-related musculoskeletal disorders. in the manual loading and unloading of traditional workstations, employees work a day down very tired, personnel turnover is very serious, the surge in labor costs, EHS-OHT automatic loading and unloading system adopts a digital interactive interface, the work has become easier, more relaxed and intelligent, and the production efficiency has also been greatly improved.

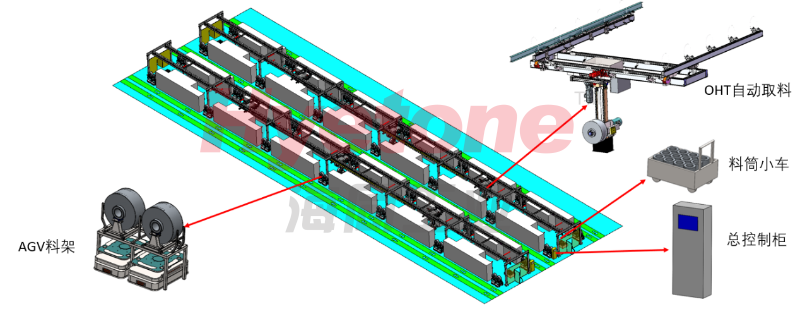

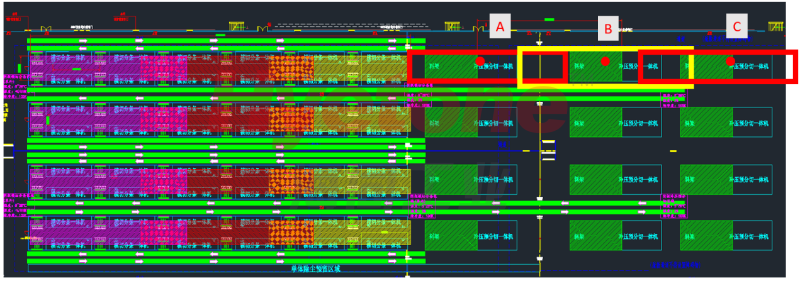

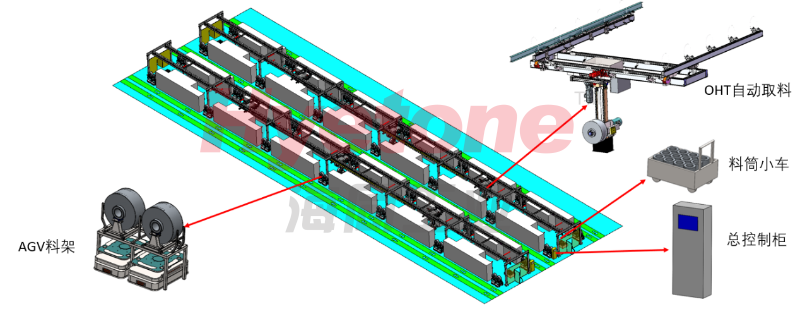

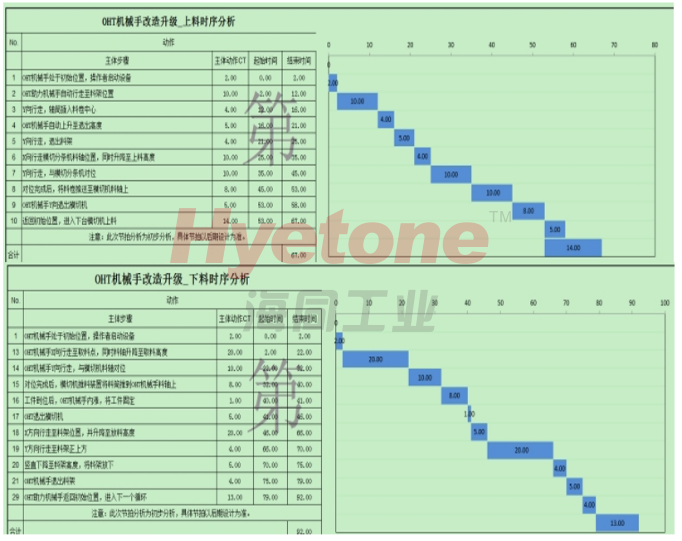

该方案主要由地面立柱龙门框架,优质 铝合金AMB轨道 ,OHT自动上下料机,AGV料卷小车,料筒转运小车,地面控制柜等组成。通过计算机系统和电控系统调度、自动控制,实现生产线的智能化和自动化。

The program mainly consists of ground column gantry frame, high-quality aluminum alloy AMB track, OHT automatic loading and unloading machine, AGV reel trolley, barrel transfer trolley, ground control cabinet and so on. Through the computer system and electronic control system scheduling, automatic control, to realize the production line of intelligence and automation.

自动化系统通过计算机运算、调度、统计、分析、管理一体化,可有效利用现场生产空间,实现工件生产和存储管理自动化、智能化、信息化,提高工件、料架、物料盒的周转,工件来料、送料、存储各环节方面工作效率,降低差错率。同时对生产线生产数据信息采集、生产过程实时监控、人员状况分析等,把生产、设备、人员和物料有机结合一体,促进生产管理水平的提高。

Through the integration of computer computing, scheduling, statistics, analysis and management, the automation system can effectively utilize the on-site production space, realize the automation, intelligence and informatization of workpiece production and storage management, improve the turnover of workpieces, shelves and material boxes, and the efficiency of workpieces' incoming materials, feeding and storing in each link, and reduce the error rate. At the same time on the production line production data information collection, real-time monitoring of the production process, personnel status analysis, etc., the production, equipment, personnel and materials organically integrated into one, to promote the improvement of production management level.

海同工业 AMB人机交互智能助力装备 系统应用于物料移载、高频率搬运、精确定位、部件装配等场合;可极大减轻工人的劳动强度,提高生产效率、保障产品质量,人机交互智能助力装备系统的应用符合现代化工厂柔性制造的趋势,提升生产线附加值,是现代工业的重要组成部分。海同工业通过对卷料生产现场产线的科学改造和设备升级,对比改造前产能,可实现产能提升150%。目前的海同工业OHT机械手改造升级自动上下料方案在艾利(中国),宁德时代,及碳纤维上市公司等已开始应用。

AMB Human-Machine Interaction Intelligent Assisting Equipment System is applied in the occasions of material moving, high-frequency handling, precise positioning, component assembly, etc.; it can greatly reduce the labor intensity of the workers, improve the production efficiency, and guarantee the quality of products, and the application of AMB Human-Machine Interaction Intelligent Assisting Equipment System is in line with the trend of the modernized factory's flexible manufacturing, and enhances the added value of the production line, which is an important part of the modern industry. Through the scientific transformation and equipment upgrading of the production line at the coil production site, Hyetone can realize a 150% increase in production capacity compared to the capacity before the transformation. Currently, Hyetoe OHT robotic transformation and upgrading of automatic loading and unloading solutions have been applied in Avery (China), Ningde Times, and carbon fiber listed companies.

Tel.

Tel.