China's statistics on production logistics, machinery factories produce 1 ton of finished products, need to carry out 252 tons of loading and unloading handling, and its cost is 15.5% of the processing cost.

Production is destined to be accompanied by material handling, material handling weight is often several times the weight of the product, or even dozens of times. In the United States, the cost of loading and unloading accounted for 20-30% of the total cost; German enterprises material handling costs accounted for 1/3 of the turnover; Japan material handling costs accounted for 10.73% of GDP. In China, the beginning of railroad transportation and reach the handling operation fee roughly accounted for about 20% of the freight, shipping accounted for about 40%.

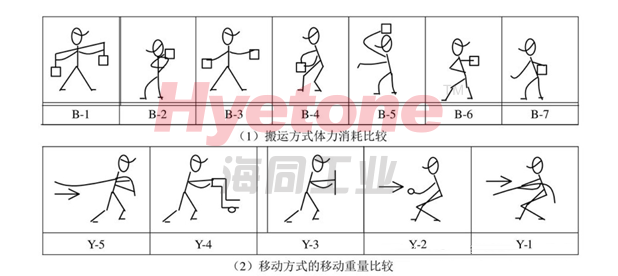

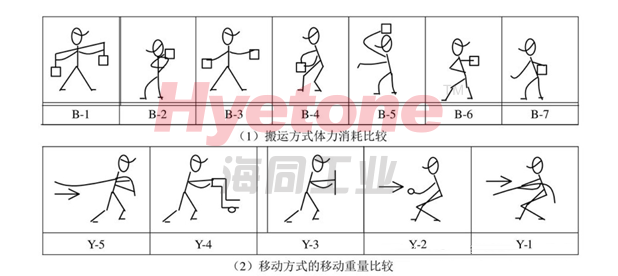

Ergonomics and handling in the handling of small items, to B-1 way that is, the shoulder way the most labor-saving, and B-7 way the most laborious, in moving heavy objects, to Y-1 way may move the weight of the largest, and Y-5 way may move the weight of the smallest.

No matter what, industrial workers move unloading assembly every day, day after day, we still need to use our brains, how to make our work easier with the help of equipment.

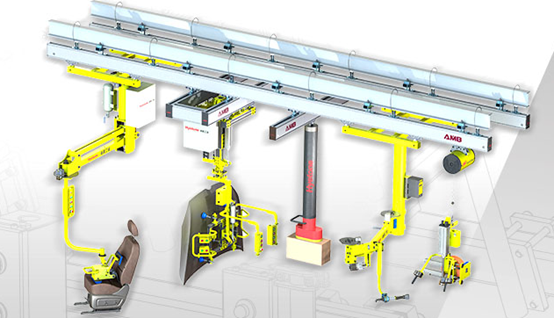

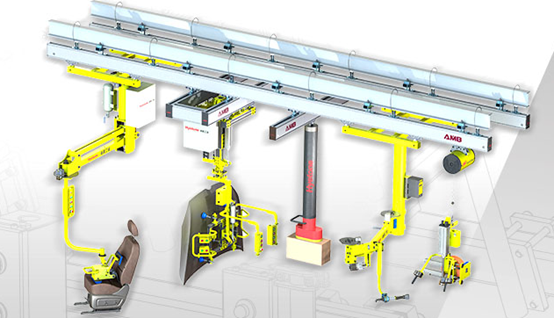

Machinery for loading and unloading handling:

Hyetone Human-Machine Interaction Assisted Mechanical Handling Device

Machinery used to move, lift, load and unload, and short-distance transportation of materials or goods, to assist industrial workers in the production of assembly is also known as power-assisted manipulator.

The development of power-assisted manipulator technology is gradually playing a greater role in industrial production. In recent years, productivity and ergonomics issues have increasingly motivated producers and users of material handling equipment to develop and apply new equipment and systems.

Hyetone Industrial EXO Intelligent Booster Manipulator can fundamentally improve the labor conditions of workers, reduce labor intensity, and improve the man-machine environment. One of the most important problems with traditional material handling equipment is health-related ergonomics. The lack of inertia management of payloads leads to operator fatigue, stress and, in more serious cases, musculoskeletal disorders (MSD). Work-related back disorders are also on the rise in Europe. According to the European Safety and Health Agency (OSHA), about 30% of European workers suffer from back pain, mainly due to excessive physical demands, such as lifting or manual handling of loads, repetitive motions, and tiresome postures. The social, health and economic costs of this problem are substantial, and it is estimated that the cost of overworked workers' illnesses ranges from 2.6% to 3.8% of the gross national product of member states. With the acceleration of industrialization in China, the labor environment of workers as well as ergonomic problems have received increasing attention from our government.

In the automotive assembly welding production line, line to line connection or inter-station parts transfer need to arrange and design a reasonable conveying program, which is the modern large industrial production mechanization, automated production requirements.

Domestic mainstream automobile adjustment line, including Hyetone industry to provide products and services of several large-scale advanced automobile factory's automobile adjustment line site, we can see that its assembly welding workshop adjustment line has been using ordinary simple fixtures, the workers are hand-held simple fixtures manually tighten the operation, resulting in the consistency of the entire car effect is poor, and then need a lot of manual to adjust the mold repair, increase labor intensity, and the workload, which has a great impact on the production beat. The workload is large, which has a great impact on the production rhythm, and it is not possible to produce for a long period of time. However, due to technical reasons, multiple shifts have been used to solve this problem.

After observing the customer site, Hyetone design engineers found that the original assembly process can be changed to realize automatic tightening at certain stations, and improve the unstable consistency of the products after tightening to increase the assembly accuracy and save time. After verification and discussion, the automobile factory hoped to use the human-computer interaction booster equipment provided by Hai Tong Industry to combine with the complex bodywork to achieve the high-frequency precision operation with a production beat of 57 seconds, to fully reduce the labor intensity of the workers and to achieve the high-quality consistency performance.

The complex fixtures designed by Hai Tong Industry for the adjustment line of an advanced mainstream automobile factory are the most advanced design in China at present. The process design of the adjustment line of the second phase of this automobile factory is a mixed line production of three models, and the design engineers of Hyetone designed a whole set of customized chemical fixtures that fully benefit the space, equipment, materials, and personnel's close connection and reasonable distribution, so as to maximize the efficiency and benefit of the customized chemical fixtures by fully inspecting each work station.

After more than a month of on-site installation and debugging, the automotive assembly welding production line replaced with the man-machine interaction provided by Hai Tong complex tooling spreader, the automotive plant adjustment line fixtures a new look, the field workers reflected that compared with its previous simple tooling, due to the consistency of more stable, unanimously reflected the reduction of subsequent adjustment and grinding workload, reducing their labor intensity, and easier to operate than the previous simple fixtures. In addition, it is easier to operate than the previous simple fixture, and the production tempo has been greatly improved as precise assembly can be realized by simply operating a few buttons.

The production site of automobile adjustment line is interlocked, which is concerned about the production rhythm and efficiency, how to create efficient and labor-saving human-machine interaction assisted fixtures is the theme of the production line fixture design of Hai Tong, Hai Tong industry through the site site visits and in-depth discussions with the staff, designed for the automobile factory highly customized fixtures and give full consideration to human-machine integration of the adaptability, which mainly includes:

Through customized assembly jigs, headlight bracket fixtures, four door lower hinge fixtures, front cover hinge fixtures, rear cover fixtures, wing panel A-pillar fixtures, wing panel front fixtures, checking fixture samples, and the adoption of international advanced honeycomb-type AMB high-strength aluminum alloy track system, all kinds of related precision problems have been solved, and the positioning is more accurate and stable:

1, to ensure the four doors and two covers and the body of the rigid connection, to ensure that the body assembly and the gap between the various parts of the connection and surface accuracy. Workers reflected after using the assembly jig flexible operation. The assembly fixture combines pneumatic and electric control, high degree of intelligence and automation, all positioning and clamping points are arranged in the body RPS points, accurate positioning, high repeatability, to ensure the stability of the body assembly.

2. The checking sample is used to assist and verify the precision and stability of the assembly adjustment between the four doors and two covers and the body.

3、The on-site AMB track system adopts the international advanced honeycomb type high strength aluminum alloy track with high strength, high precision, less than 2kg pushing resistance, low noise and maintenance free. And equipped with buffer limit travel switch, and automatic conveyor main line for signal interlocking, to ensure the safety of equipment operation, not due to over-travel and collision failure, damage to the body, equipment, causing personnel injury. Completely solved the defects of poor precision, high resistance, high noise and bulky operation caused by the use of steel rails in traditional automobile enterprises.

4、The headlight bracket fixture adopts manual clamping, with the spring balancer to assist lifting, can be quickly positioned; save operating time while increasing the stability of the fixture to avoid loosening affecting the positioning accuracy of the headlight bracket.

1 、四门下铰链装具为一体式装配,利于气动夹紧缸,保证四门下铰链的位置准确,同轴度高,为后面四门装配提供安装基准,利于前后门的间隙及平度控制。

2、前盖铰链装具为一体式装配,通过一体式装具的装配,铰链的定位精度得以保证。另外装具操作时序与铝合金人机交互助力T型臂主机动作进行联动互锁,防止因误操作产生车身和设备的损坏。

3、 后盖装具集成取件、定位装配功能一体,采用自动感应联锁动作,确保后盖稳定,精度高。

4、翼子板A柱装具利于前门做固定基准,通过吸盘、间隙块、气缸控制翼子板与车门的间隙和平度,精度得以保证。

5、 翼子板前端装具为左右一体式,避免白车身在主线上的状态与装具主机的位置不一致导致卡滞,定位偏差,从而影响翼子板的装配精度。

Hyetone定制汽车厂吊具

海同通过定制化的平衡助力机械手、高精度铝合金T型臂、翼子板小件装具、四门吸盘式吊具、前盖闭合打紧装具、前盖装配吸盘式吊具等是的操作更灵便,节省生产空间及装配的时间及设备成本,大大提高了工作效率:

1、定制化平衡助力机械手采用高精度铝合金T型臂并配有气动和电动控制,采用进口高规格气动件、标准件,设备轻巧,操作力小,移动便捷,定位精准,维修方便。而传统的提升主机无定位操作,晃动大,不利于装具精准定位,影响操作效率。

2、翼子板小件装具为单侧手推车一体式,消除了翼子板小件的错位而导致后续翼子板的装配精度的隐患。

3 、四门装配为吸盘式吊具,配轻便的铝合金人机交互T型臂助力主机辅助作业,操作灵便,可灵活对位装配,集成度高,节省空间、时间及设备成本。

4、 前盖闭合打紧装具为自动拧紧作业,将前盖在闭合状态下进行拧紧,确保前盖与翼子板的间隙和平度满足装配精度要求,同时提高工作效率。

5、 前盖装配为吸盘式吊具,配合人机交互软索式折臂吊主机,配合前盖闭合打紧装具辅助作业,并通过间隙块定位,操作便捷,可灵活对位装配,集成度高,节省空间、时间及设备成本。

Hyetone定制汽车厂吊具