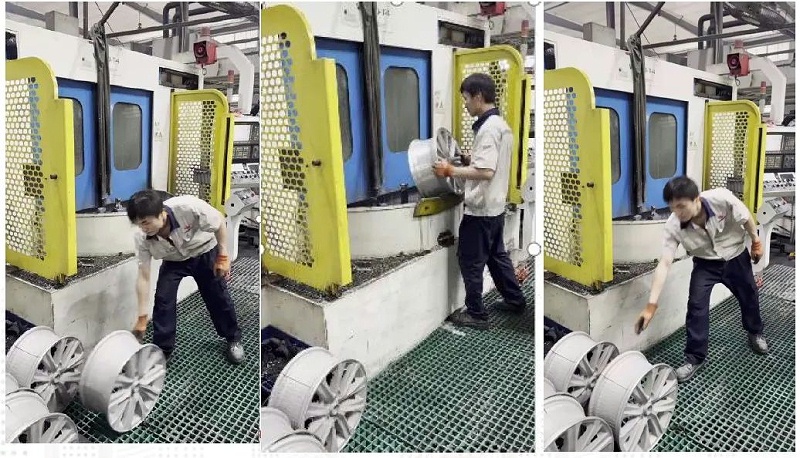

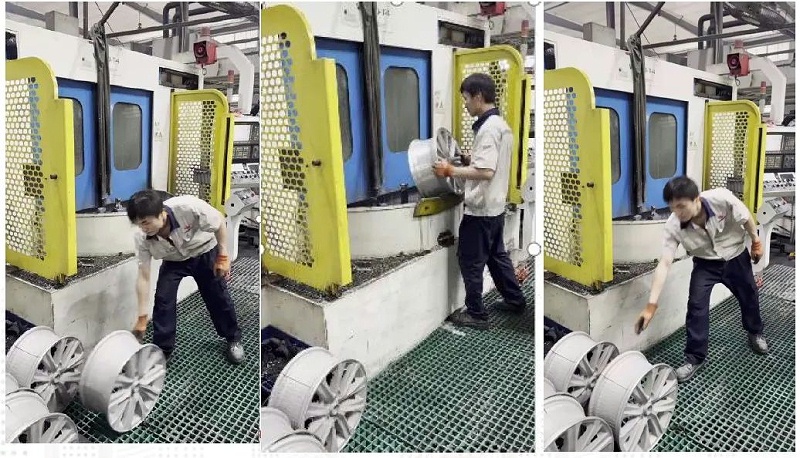

During the loading and unloading process of wheel machining with a low level of automation, the workload of the line employees is extremely heavy, with frequent operations such as lifting and measuring. This makes it urgent for companies to improve production quality and efficiency through automation upgrades.

At the same time, with rising labor costs and the high retrofit and aftermath maintenance costs of traditional six-axis robots, many aluminum wheel machining companies have encountered difficulties in seeking automation solutions. Hai Tong Industry, which is committed to human-robot interaction and intelligent equipment, has launched AMB™ Pure Visual Perception Composite Robot from the basic technical needs of industrial assembly and load shifting, which can be an ideal alternative to manual labor to realize efficient production by guiding flexible automatic robots with a purely visual camera.

The AMB™ vision-only composite robot has redefined the industry solution for millimeter-precision assembly:

The following comparisons clearly show that the AMB™ composite robot overcomes the shortcomings of traditional 6-axis robots in a number of ways, providing organizations with a more flexible, efficient and cost-effective automation solution:

Conventional

Underutilized six-axis robots

AMB™

Pure Visual Perception Composite Robot Advantage

Economical.

Fast payback of investment

High initial investment, especially the reliance on high-end sensors and complex machine vision hardware, leads to a significant increase in system costs.

Through the pure visual perception technology and four-axis robot form, it significantly reduces the overall system cost, which is only one-third of the use cost of traditional robots, enabling SMEs to easily automate and quickly recover their investment.

Simple structure

No need for enclosure

The structure is more complex, and to protect the safety of field use, the machine must enclose the hardware and sensor configuration, making installation and maintenance more difficult.

Simple construction eliminates the need for additional enclosures and complex safety sensing configurations, simplifying installation and operation, thereby reducing failure rates and increasing ease of maintenance and operation.

The freedom of movement is high, but once programming and calibration are complete, it is difficult to make trajectory adjustments and is not flexible enough.

Using a four-axis design, although there are relatively few degrees of freedom of movement, the combination of highly efficient visual perception technology allows for real-time intelligent recognition in complex environments and ensures a higher level of adaptability.

In high-speed movement or heavy load, the rigidity of the six-axis robot with the use of the cycle increases, will lead to reduced motion accuracy, trajectory deviation, especially in the domestic low-end six-axis robot is even more difficult in this regard.

High-precision vision processing and artificial intelligence algorithms are used to ensure millimeter-level real-time intelligent recognition and positioning adjustment during use, maintaining motion accuracy and reliability.

Fixed trajectories and cumbersome programming processes make six-axis robots cumbersome to adjust in response to changes in the workpiece, affecting operational efficiency.

With intelligent learning and self-adaptive capabilities, it can quickly respond to environmental changes and optimize operational efficiency, ensuring the continuity and stability of the production line in a dynamic working environment, so that it maintains a high attendance rate. At the same time, it effectively reduces the risk of human error.

Multitasking capabilities are limited and often require large hardware changes to accommodate different applications.

Enables multi-tasking of handling, assembly, and sorting through visual perception without extensive hardware modifications, increasing versatility.

Easy Integration

and Programming

Reliance on complex control systems complicates system integration and programming, with a high threshold for after-sales service.

The simple structure, using an optical camera to collect visual data and apply software algorithms, reduces reliance on complex control systems, makes system integration easier, speeds up the deployment process, and lowers the threshold for after-sales maintenance.

1. Vision unit “Eye”

AMB™ pure visual perception composite robot has five levels of learning ability from “primary learning” → “experience learning” → “adaptive learning” → “comprehensive learning” → “continuous learning”. AMB™ has a five-level learning ability from “primary learning” → “experience learning” → “self-adaptive learning” → “comprehensive learning” → “continuous learning”. The vision unit can adapt to a variety of scenarios and actual changes in wheel processing and loading and unloading, and it has the ability of self-learning and self-improvement, as well as adaptability and flexibility not found in six-axis robots. It has the following key features:

-

End-to-end AI:

The AMB™ vision unit “Eye” technology uses an end-to-end neural network to process the image data input from the camera and directly output action decisions such as positioning, assembly and inspection.

Pure Visual Perception:

Relying entirely on a pure vision system eliminates reliance on millimeter-wave radar and improves system flexibility and accuracy.

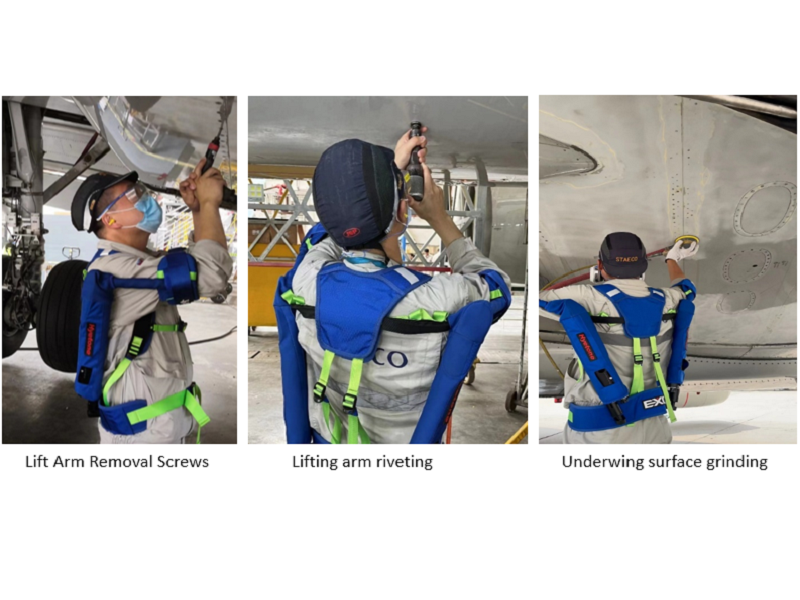

Human-machine collaboration:

Equipped with a “human eye” function that adapts to the worker's position and movements, enabling safe and efficient automated assembly.

Data-driven and continuous optimization:

The AMB™ vision unit learns and optimizes from real-world data to continuously improve the performance of automatic recognition and motion algorithms.

Safe by Design:

The system retains the human-robot collaboration switching function, which allows the operating worker to take over the robot at any time, and the robot's working process does not need to be shielded to ensure safe operation.

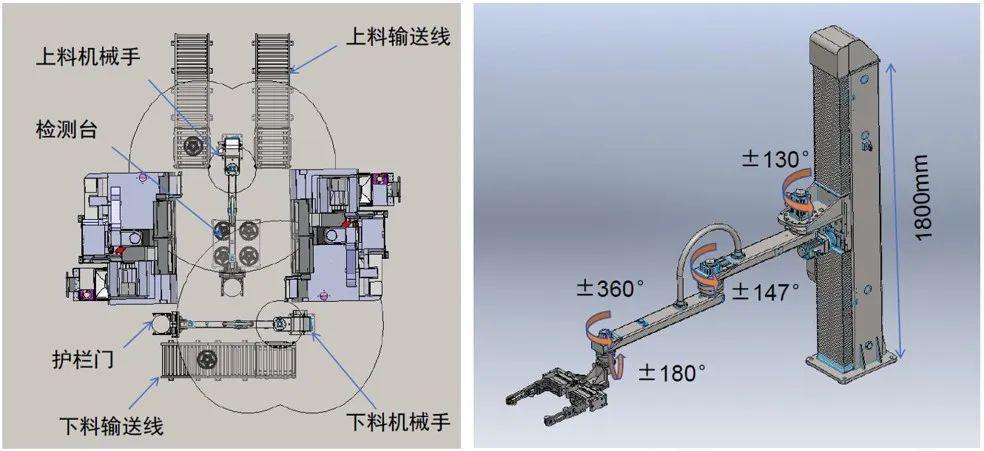

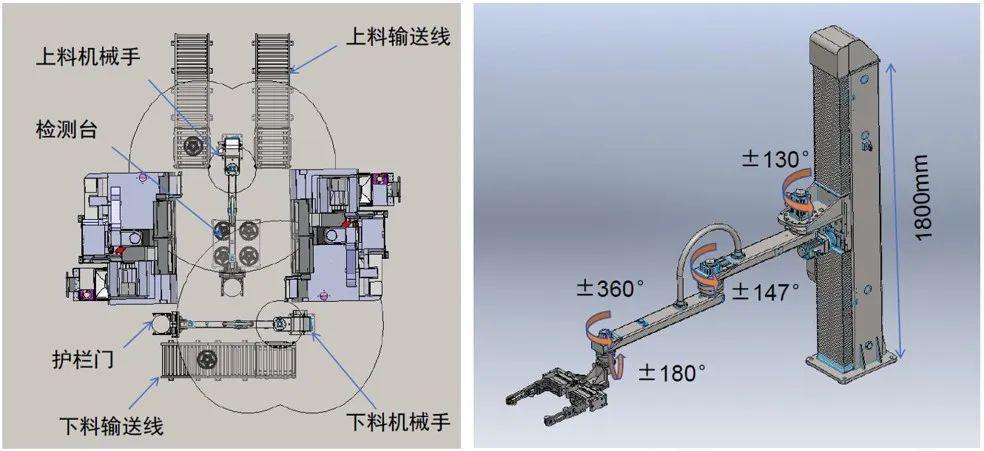

2. Lifting cell “body”

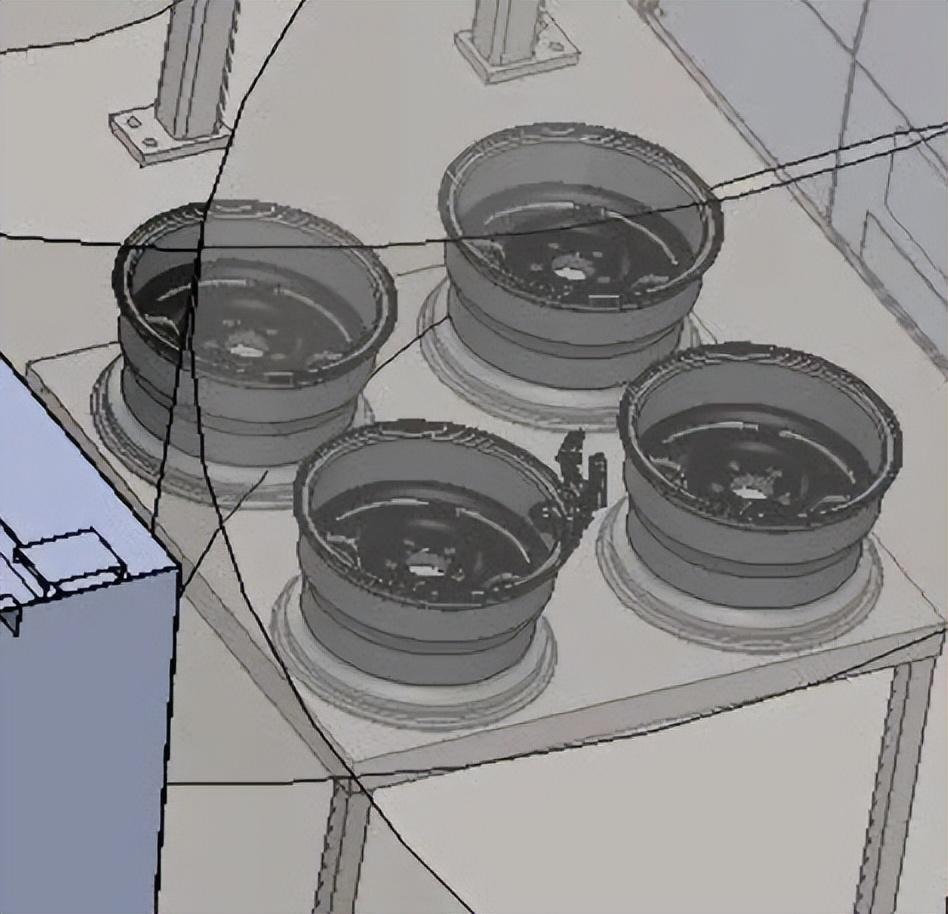

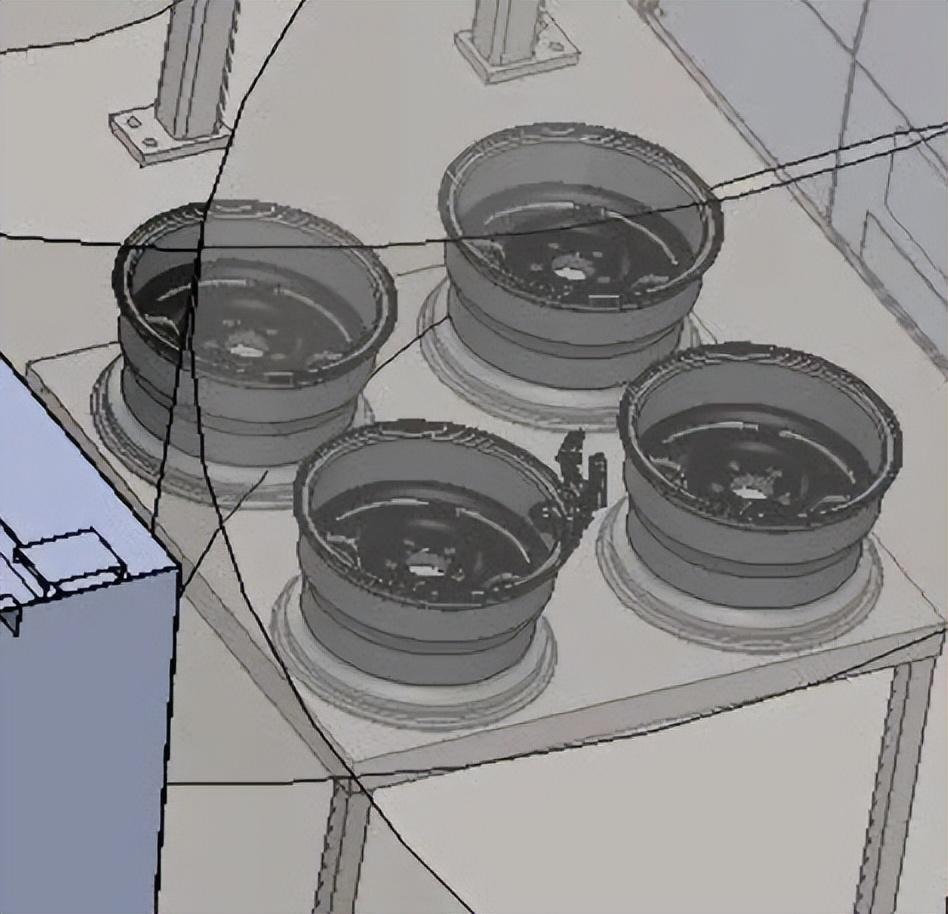

In the AMB™ purely vision-aware composite robot solution for wheel loading and unloading, the lifting cell is a column-mounted, stiff-armed manipulator with a flexible design for smooth operation and easy handling, making it ideal for daily work;

Different rotation angles for each joint (for easy pick-up). Providing higher flexibility, together with the vision auto-positioning function, fully automatic loading and unloading of workpieces on the wheel hub can be realized.

In addition, the “body” of the AMB™ Pure Vision Composite Robot can be designed with a T-type or torsion-resistant arm, depending on the requirements:

-

T-type structure: independently developed, suitable for various industries, with suspension lifting function, suitable for rigid guidance and automatic walking scenarios;

Anti-torsion robotic arm: designed for light assembly, supporting 400N-m anti-torsion, modular design to adapt to a variety of working conditions;

3、Gripper unit “hand”

Adopting electric or pneumatic clamping jaws for gripping, it is designed according to the shape and functional characteristics of the adapted workpiece to provide gripping and positioning, forming a human-computer interaction, gripping, assembly flexibility and stability.

4. Drive unit “leg”

AMB™ pure visual perception composite robot can also be equipped with an optional intelligent walking platform, with motor direct-drive drive matched with pure visual guidance system integrated AMR, to achieve automatic obstacle avoidance and collision avoidance, can be adapted to the complex ground, breaking through the limitations of the work scene, to ensure efficient operation in the work area.

For solution details or price inquiry, please call the product service hotline +86 400-018-2086 or add Whatsapp as below: