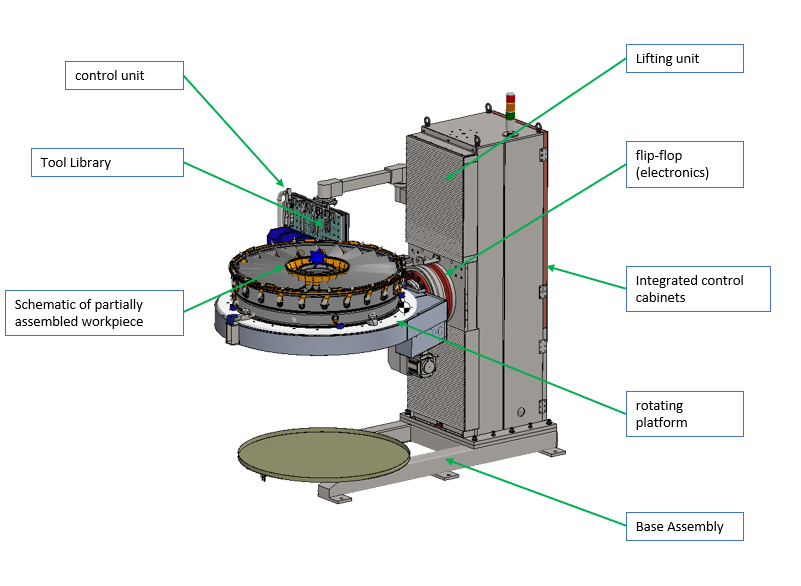

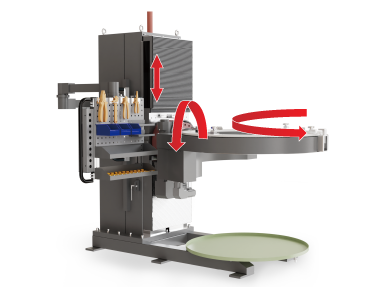

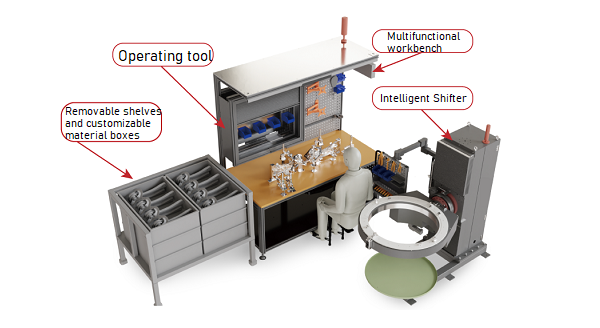

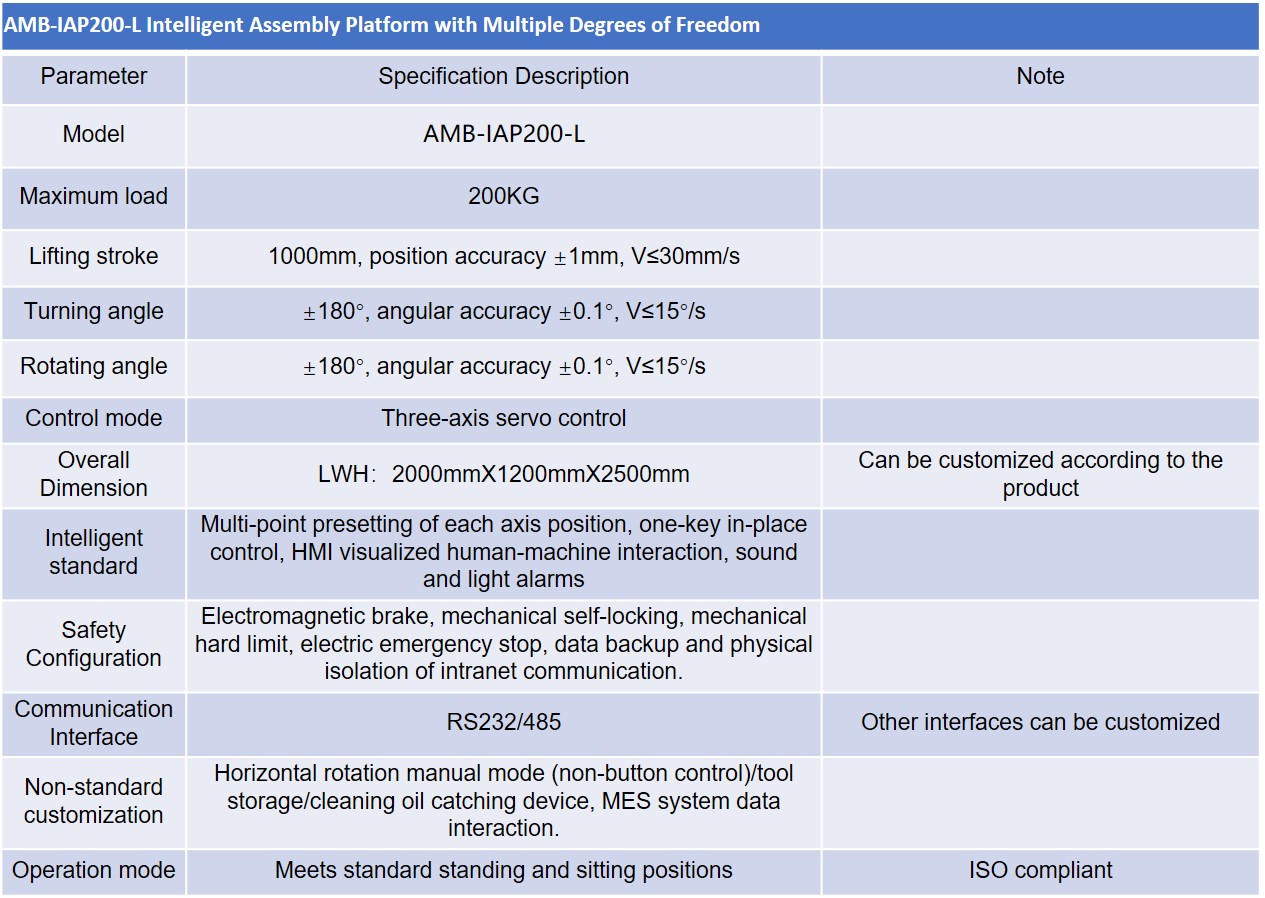

AMB-IAP multi-degree-of-freedom intelligent assembly platform is mainly composed of base, lifting unit, flip unit, rotating unit, electronic control system, adapted tooling and human-machine interaction control unit, configured with unified MES expansion interface, with its multi-axis degree-of-freedom transformation, flexible attitude adjustment function, a high degree of intelligent operation platform is widely used in the aviation industry engine parts or the whole machine assembly operation, quality inspection, but also At the same time, it is also suitable for welding positioning and attitude adjustment of all kinds of heavy industry parts, which is suitable for robot automation. The main features of AMB-IAP Multi-degree-of-freedom Intelligent Assembly Platform are as follows: 1、Single column form, minimize space saving, maximize 270°working space; 2、Multi-axis intelligent and precise control, all-around variable position in each working attitude, perfect man-machine cooperative work; 3、Maximum load can be up to 3.5t, strong load capacity, stable operation of all axes, silent operation , fast response; 4, modular design, hardware compatibility, customized development, commissioning and maintenance is convenient and fast; 5, digital interaction, intelligent control, compatible with the enterprise-level digital production line management; 6、Configuration of multiple safety features, in line with and better than the aviation industry equipment standards;

Guangzhou Hyetone Industrial Technology Co., Ltd. (Hyetone), established in November 2004,in Guangzhou, Hyetone has adopted a differentiated competitive strategy in the intelligent equipment market segment, and formed a series of intelligent equipment host series products with distinctive technical highlights and highly differentiated competitiveness with "Ergonomic improvement Technology" as the core, such as "human engineering, profiling technology, motion capture, motion recognition, tactile interaction, life monitoring, simulation simulation"

EXO Titan Arm Exoskeleton - Cost-effective and Innovative Solutions for Aviation Maintenance

AMB™ vision robots save up to 70% on wheel loading and unloading and increase efficiency!

Chinese brand - Hyetone AMB™ helps Sallis factory to build stable quality for the world's leading automobiles

Innovative Application of AI Vision Inspection Technology in Industrial Grade Measurement - Catheter Digital Measurement System

Lean Manufacturing,Line-side warehouse air track application - warehouse moves with people, tools move with the line

Making PPE the Right Fit for All

New energy industry coil OHT intelligent loading and unloading to help the robot application of the planning

Hyetone Industry: Why do they say KBK flexible rail is a very practical rail equipment?