Lean Production (Lean Production, or LP for short) is the acclaimed name of several experts from the Massachusetts Institute of Technology's International Motor Vehicle Program (IMVP) for Japan's "Toyota's JIT (Just In Time) production method".

Precision, i.e., less and more precise, do not put in excess production factors, but only in the appropriate time to produce the necessary amount of market demand for products (or the next process urgently needed products); Benefit, i.e., all business activities should be beneficial and effective, with economic. That is: a variety of modern management methods and means, based on social needs, to give full play to the role of people based on the effective allocation and rational use of enterprise resources, maximize the economic benefits for the enterprise a new type of production, is the current industrial world's best kind of production organization system and method.

Toyota Motor, as the pioneer of lean production and a global benchmark model, can often be seen in its automobile production line, the production line is "fluidized" and "mixed-flow production". Although different varieties of mixed production, but a small number of varieties of production, like the same variety of mass production, can be carried out freely and smoothly - for example: automobile factory assembly production line is very long, each vehicle has a large number of parts and components, so in the production line next to the positions are required to temporarily store a number of parts to ensure the continuity of production. How does Toyota optimize operations:

The use of three-dimensional storage areas along the line to create an aerial production line, realizing the three-dimensional layout of the entire manufacturing space, making the production and manufacturing more rational and orderly, forming a human-machine-material-fa-ring circulation.

The operational layout of a wire-side warehouse plays an important role in the automotive industry.

Lineside storage, not really a warehouse, usually refers to tooling shelves, which can be used as small workbenches or supply bins for auxiliary tools such as record sheets, tightening guns, scanning guns, and monitors. In some companies outside of the automotive industry, the lineside warehouse can hold raw materials, parts, etc., in addition to finished and semi-finished products.

In addition, the track aerial layout of the wire-side depot has the same application in the maintenance workshop of branded automobile 4S stores.

As an extension from the automobile manufacturing to reach the user, 4S stores are the primary channel for automobile brands to dock with customers, some excellent automobile service 4S stores synchronization also began to learn the lean manufacturing method, the maintenance workshop to enhance the transformation, the integration of wire-side aluminum track for air layout, tools, air tubes, and wire groove alignment, etc. is no longer disorderly layout, the use of wire-side track of the scientific layout makes the maintenance layout more integrated, rationalization, to To achieve lean manufacturing, to provide customers with efficient, high-quality maintenance services, more reflective of the brand value.

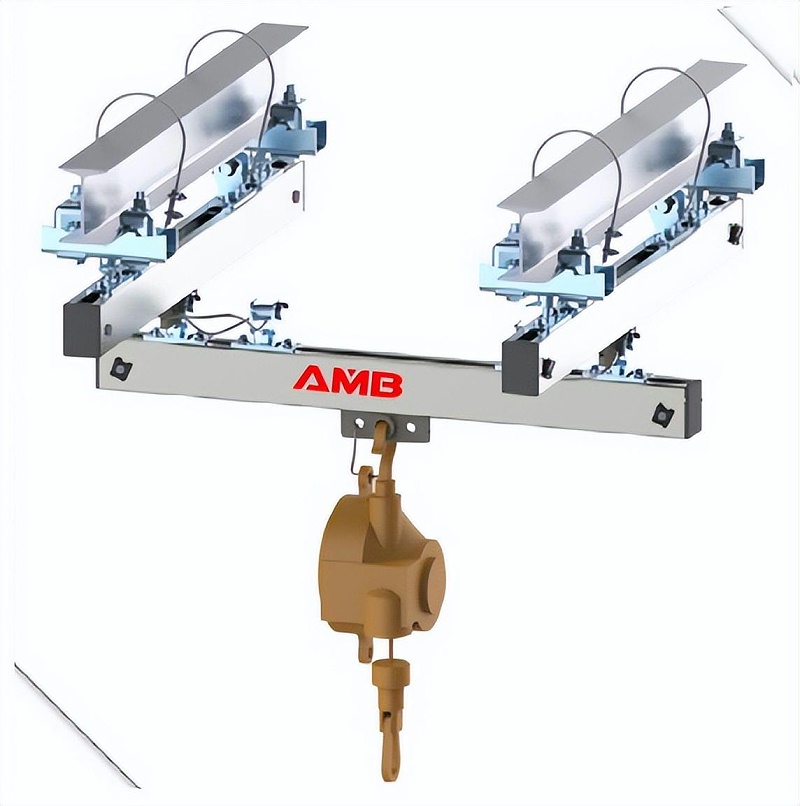

Over head aluminum track, i.e., lineside rail (tool rail) + material rack (cart), the form of three-dimensional layout of the lineside warehouse is one of the links of lean production and logistics planning.

Lineside Aluminum Rails vs Steel Rails

The AMB™ line-side aluminum rails originated from Toyota Motor Corporation. In automotive assembly sites, especially in final assembly shops and welding and adjustment lines, the assembly of cars often cannot be replaced by automated equipment, and a large amount of work needs to be handled by production line employees. During the process, employees need to use more fixed tools or consumables, and must follow the movement of the production line to complete the assembly of all vehicles on the production line. How to use these materials efficiently has a direct impact on production efficiency and quality. In material management, air rail system is a common tool. Traditional steel rails have the advantage of high load carrying capacity, but they also have disadvantages such as high weight and high operating force. In contrast, AMB™ Aluminum Ledge Rails, a new type of aluminum alloy rail with a complex cross-section and a clean appearance, also known as tool rails, offer the advantages of light weight, light handling, aesthetics, resistance to corrosion, ease of cleaning, and more flexibility than can be ignored. The use of aluminum rails can make material management more convenient and efficient, reduce the accumulation of materials and chaos on the production line, and improve production efficiency.

Walking Racks vs. Floor Trolleys

Walking shelves and floor trolleys are two common types of material transportation tools. The traditional ground trolley is easy to operate, but there are problems such as the trolley's traveling is limited and the material is easy to be damaged. While the traveling material shelf can be commonly used assembly tools, Kanban, electronic screen, etc. can be planned in the material shelf, driven by the line edge rail, according to the production staff of the beat to follow, to avoid unnecessary round-trip application of personnel.

Through the use of lineside aluminum rails, the material management on the production line is more convenient and efficient, not only reduce the accumulation of materials and chaos, but also save the staff's operating time. According to statistics, the use of aluminum rails compared to traditional steel rails, material management efficiency can be improved by at least 15%. At the same time, the use of follow-on shelves instead of the traditional ground trolley can reduce the waiting time for materials and personnel movement distance, thus further improving the speed and accuracy of material transportation. According to the experimental data, the use of the following material rack can make the material transportation efficiency increased by about 20%.

The AMB™ line side rails have been designed to customize the layout to meet the user's production needs, allowing for smoother material flow and reduced waiting and searching time, thus increasing productivity. The visibility and transparency of commonly used tools on the production line is also greatly enhanced, helping users to better manage and control material flow, reducing inventory buildup and material waste.

The introduction of AMB™ Line Edge Rails not only improves employee productivity, but also improves the cleanliness and organization of the production site, enhancing the working environment for employees. At the same time, the use of line edge rails also helps to reduce the occurrence of errors and defects.

Lean manufacturing focuses on the details, and these seemingly small improvements can bring unexpected benefits. Choosing tools such as wire-edge aluminum rails and follow-on shelves can not only optimize the production process and improve productivity, but also reduce production costs and improve the working environment. Therefore, on the road to lean manufacturing, we might as well start with these tiny details to help companies achieve sustainable development and competitive advantage.

For product details or to inquire about dealer channel prices, please call the product service hotline +86-400-018-2086 or add customer service WhatsApp.

丨Hyetone Industry

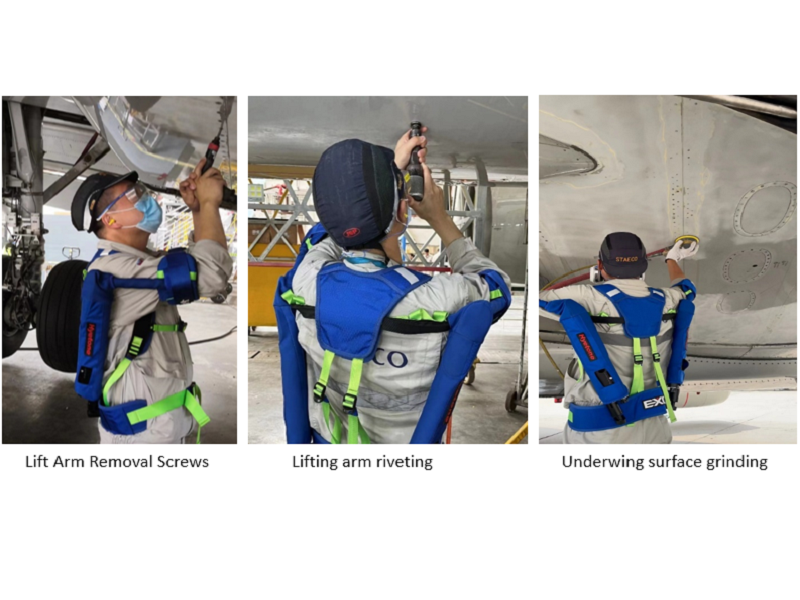

Guangzhou Hyetone Industrial Technology Co., Ltd. is a leading high-end intelligent equipment high-tech enterprise integrating R&D, design, manufacturing and marketing in China. Over the years, it has been recognized as a high-tech enterprise in Guangdong Province, Guangdong Province Intelligent Human-Machine Interaction Exoskeleton Engineering Technology Research Center, Guangdong Province Robotics Backbone (Cultivation) Enterprises, Guangdong Province Specialized and Specialized New Enterprises, and Guangzhou Municipal Research and Development Institutions. Focusing on the use of machinery and intelligence to empower industrial workers, with fluid power technology as the basis for innovation, the company adopts a differentiated competitive strategy in the mid-end and high-end intelligent equipment market segments, forming a "human-machine interaction core" with "ergonomics, morphology, motion capture, motion recognition, tactile interaction, life monitoring, simulation" and other "human-machine interaction core" products. "The core technology of human-machine interaction integrates the power of human body and machinery, reduces the burden of physical energy and amplifies the output of physical energy, and combines with the Intellidyne 5G Internet of Things platform to grasp the labor situation in real time and promote high-efficiency production.

Tel.

Tel.