characterisation

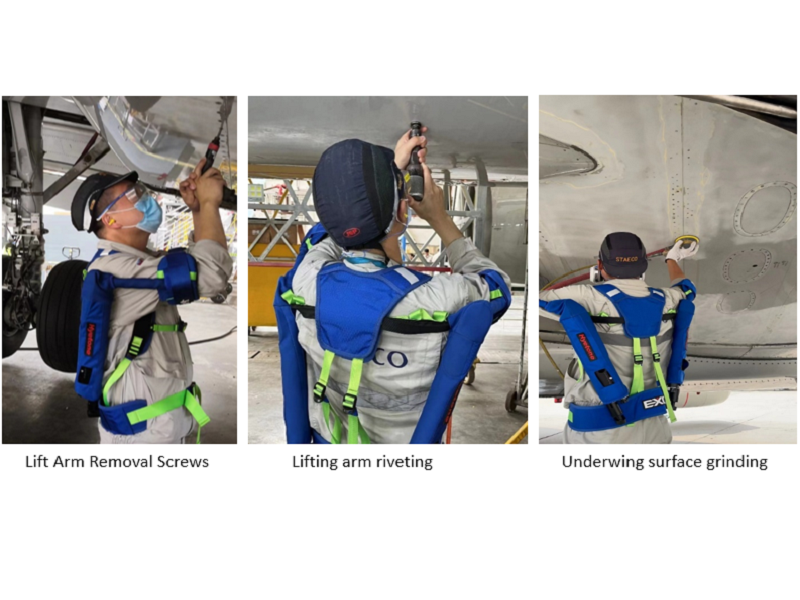

Parallel arm torsion-resistant torque, can significantly reduce the labour intensity of operation; tool clamping device with multi-directional adjustment function, easy to adjust the tool to align the fasteners; rotary joints are equipped with pneumatic brakes, can be achieved at any time to brake and fix the torsion-resistant arm of the working state, the operation is convenient; four-linkage mechanism effectively ensures that tightening the tool in the process of the consistency of the state of the lifting process; pneumatic cylinders to balance the load of the tool, the pressure is conveniently adjusted, the tool positioning and moving easily and easily; the equipment is strong to the space of the avoidance of the.

Characteristic

The reaction arm is mainly used to assist manual operation of the tightening tool, through the operation of the reaction arm, you can easily and freely lift, lower and move the tool to the best working position. At the same time, workers only need to spend the least effort to overcome the reaction torque of the tightening tool, which greatly reduces the operator's labour intensity and improves labour efficiency.

Tel.

Tel.