- Home

- Solution

-

-

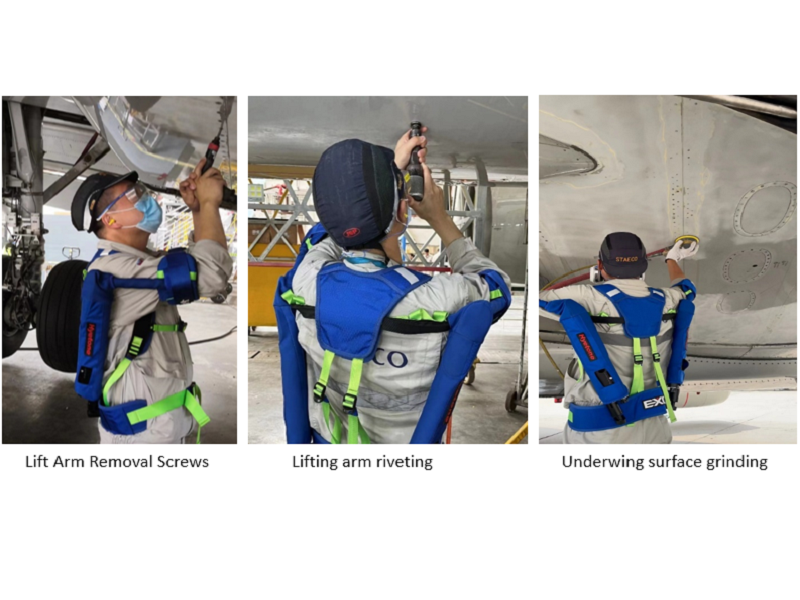

Overhead material transfer Ground material transfer Coil loading and unloading OHT Exoskeleton suit application Automobile assembly line application Automobile Welding assembly line application Application of auto parts Fuel transportation solution Auto gluing workstation Tightening system of construction machinery Loading of automobile hub application Aircraft engine assembly

-

- Products

- Case

- News

- About

- Contact

Tel.

Tel.