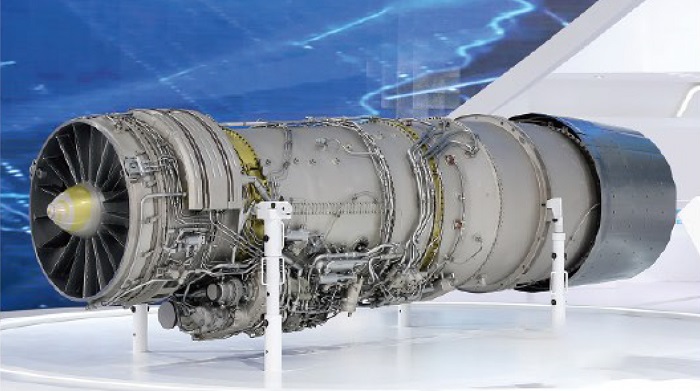

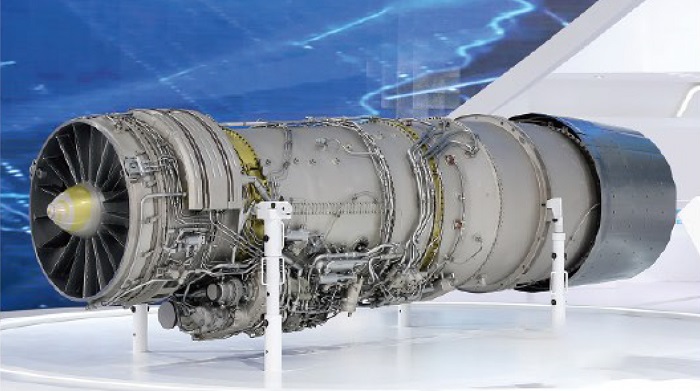

AMB-IAP Multi-Degree-of-Freedom Intelligent Assembly Platform can solve.

Automatic completion of multi-axis rotation and tilt and height adjustment of workpieces;

Servo control system for stable measurement and precise positioning of workpieces;

Workers focus on quality inspection and control work, and leave the repetitive and tedious work to the automated assembly platform;

Automatic programming and adaptive adjustment, compatible with different production requirements;

Standard MES system interface, real-time work step feedback, interconnection with production line;

ISO ergonomic design, friendly interface, comfortable operation;

AMB-IAP multi-degree-of-freedom intelligent assembly platform is mainly composed of base, lifting unit, flip unit, rotating unit, electronic control system, adapted tooling and human-machine interaction control unit, configured with unified MES expansion interface, with its multi-axis degree of freedom transformation, flexible attitude adjustment function, highly intelligent work platform is widely used in the aviation industry engine parts or the whole machine assembly operation, quality inspection, but also suitable for all kinds of heavy industry parts welding positioning, attitude adjustment, and adapted to the robotic automation operation.

Tel.

Tel.