Presentation

在轮毂生产过程,普遍采用专用设备及高精度机床加工轮毂,但上/下工件还采用人工搬运比较原始的方式。

In the wheel production process, it is common to use special equipment and high-precision machine tools to process wheels, but the upper/lower workpieces are still handled manually in a relatively primitive way.

Requirements

轮毂加工过程中经常遇到这些问题:板材或工件边沿锋利、边角尖锐,存在安全隐患; 工件粘附较多切削液,弄脏操作者衣服,还具有一定腐蚀性; 加工轮毂端面,操作者要探入机床内部装卸工件,容易刮蹭机床刀具; 上/下工件劳动强度大,工作一定时间后,不能保证原有工作效率;

Wheel machining process often encountered these problems: plate or workpiece sharp edges, sharp corners, there are potential safety hazards; workpiece adheres to more cutting fluid, dirtying the operator's clothes, but also has a certain degree of corrosiveness; processing wheel hub end face, the operator has to explore the inside of the machine tool loading and unloading of workpieces, easy to scrape the machine tool; on / off the workpiece labor-intensive, after a certain period of time, can not guarantee the original work efficiency;

Description

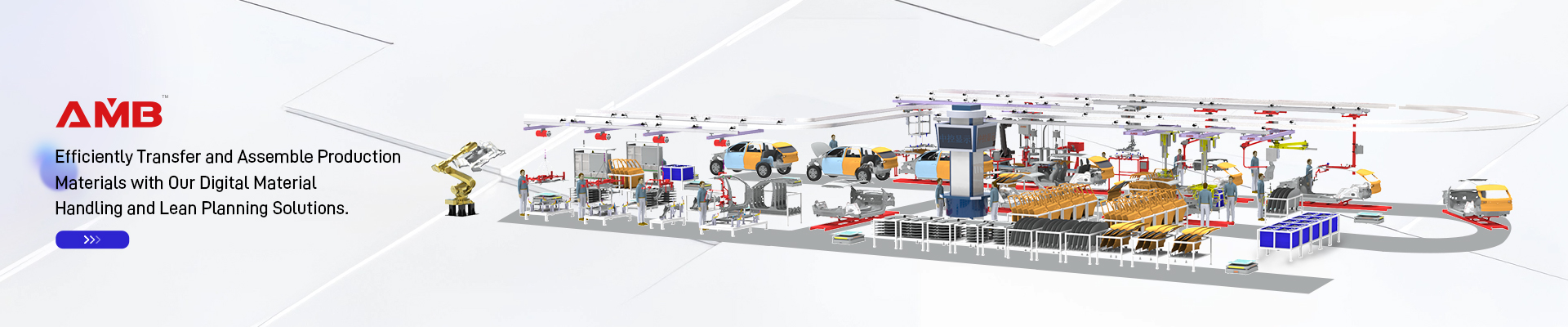

针对轮毂机架上下料海同可提供如下解决方案:√钢板搬运助力设备;√轮辐搬运助力设备; √轮毂搬运助力设备;目的:助力设备符合人机工程学,安全、简单、高效地 实现工件的抓取搬运、翻转、升降等移载工作;

For the loading and unloading of wheel racks, Hyetone can provide the following solutions: √Steel Plate Handling Booster; √Spoke Handling Booster; √Wheel Hub Handling Booster; Purpose: The booster is in line with the ergonomics of the workpiece to realize the workpiece gripping and handling, turning, lifting and other shifting work in a safe, simple and efficient way;

轮毂移载、堆垛 ; 轮毂任意加工姿态上件; 多角度翻转、 浮动对位轻松装夹 ; 操作简便、 能耗低、 安全高效 ; 轻拿轻放避免磕碰;

Wheel transfer and stacking;

Wheel loading in any machining position;

Multi-angle turning, floating alignment for easy clamping;

Simple operation, low energy consumption, safety and high efficiency;

Holding and placing lightly to avoid bumping;

Advantages

Tel.

Tel.