PRODUCT FEATURES

PRODUCT FEATURES

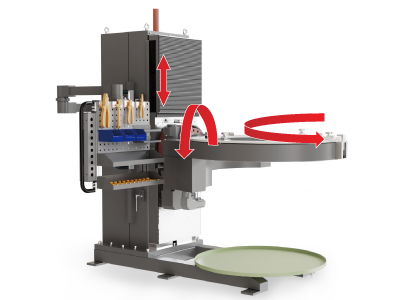

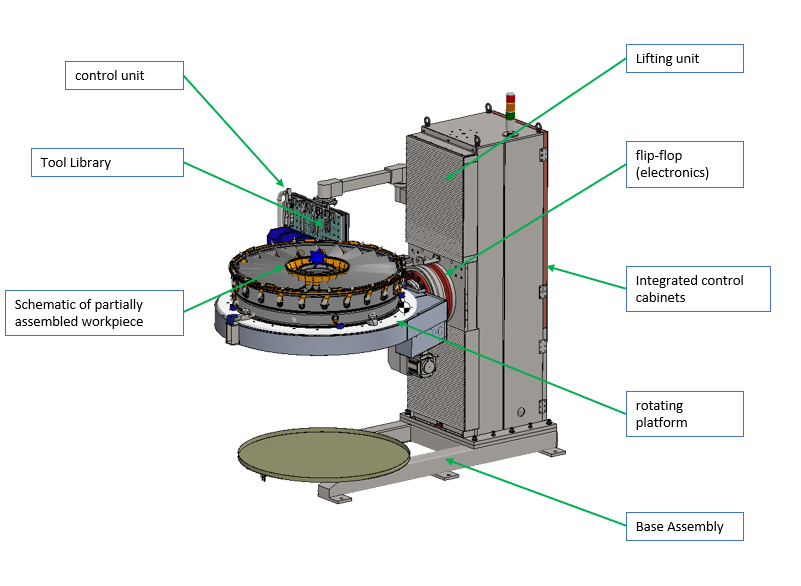

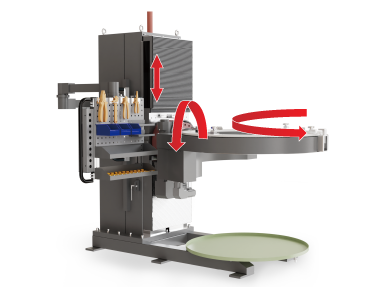

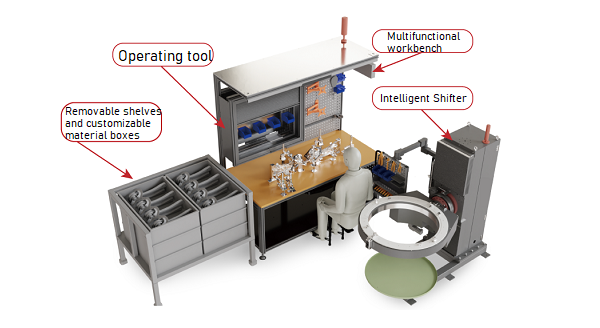

1、Single-column form, minimize the saving of occupation space, 270 ° operation space maximization;

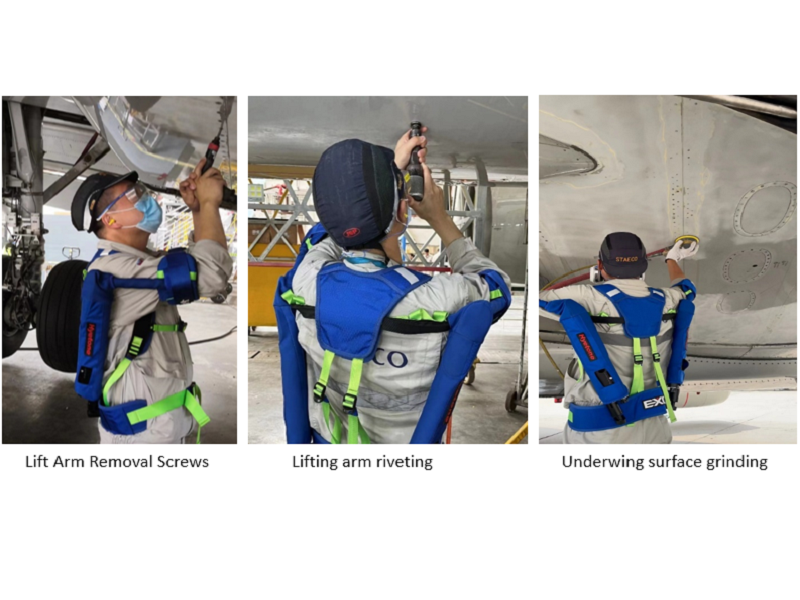

2、Multi-axis intelligent and precise control, all-around variable position of each working posture, complete man-machine cooperative work;

3、Maximum load up to 3.5t, strong load capacity, stable operation of all axes, silent operation, fast response;

4, modular design, hardware compatibility, can be customized development, debugging and maintenance is convenient and fast;

5, digital interaction, intelligent control, compatible with the enterprise-level digital production line management;

6、Configuration of multiple safety features, in line with and better than the aviation industry equipment standards;

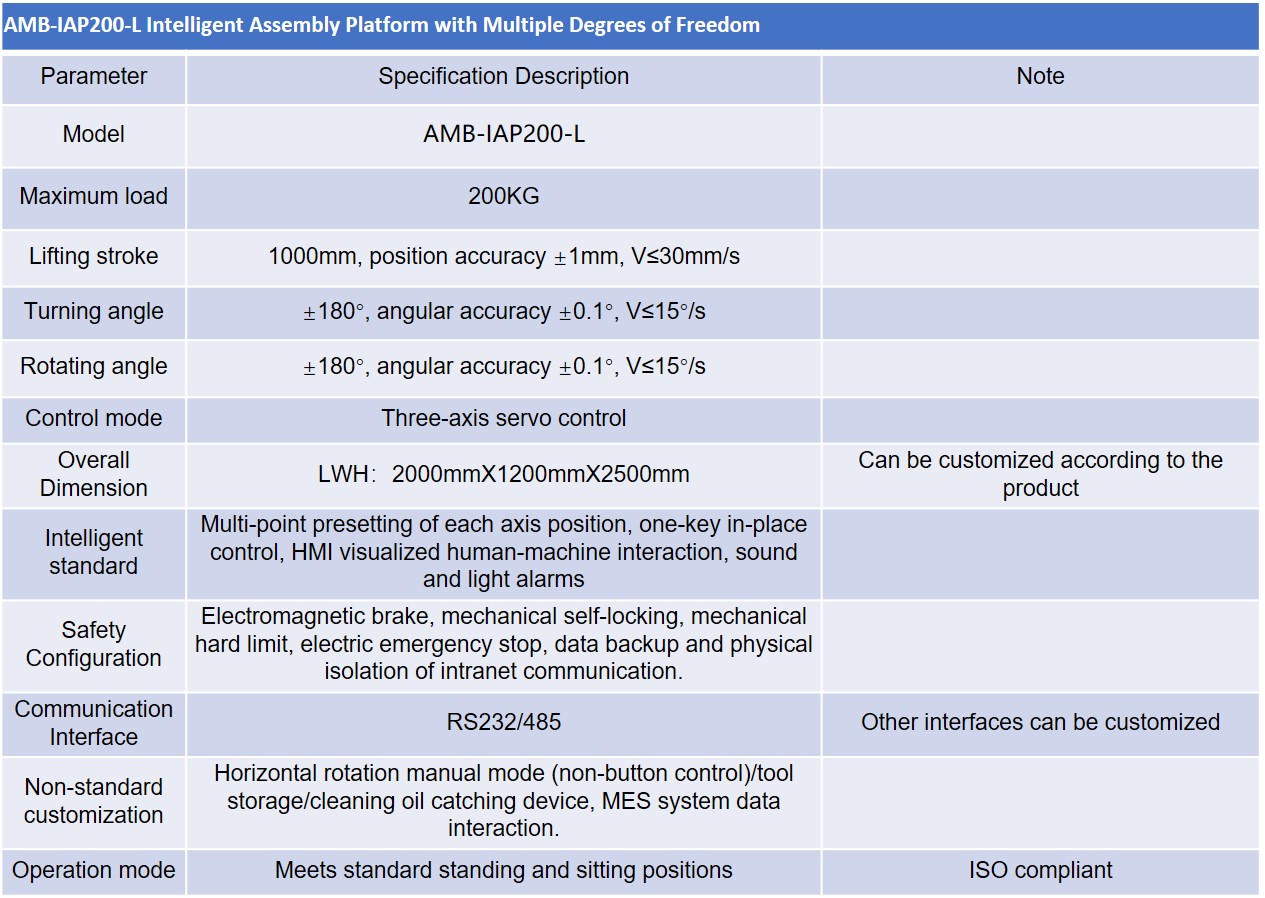

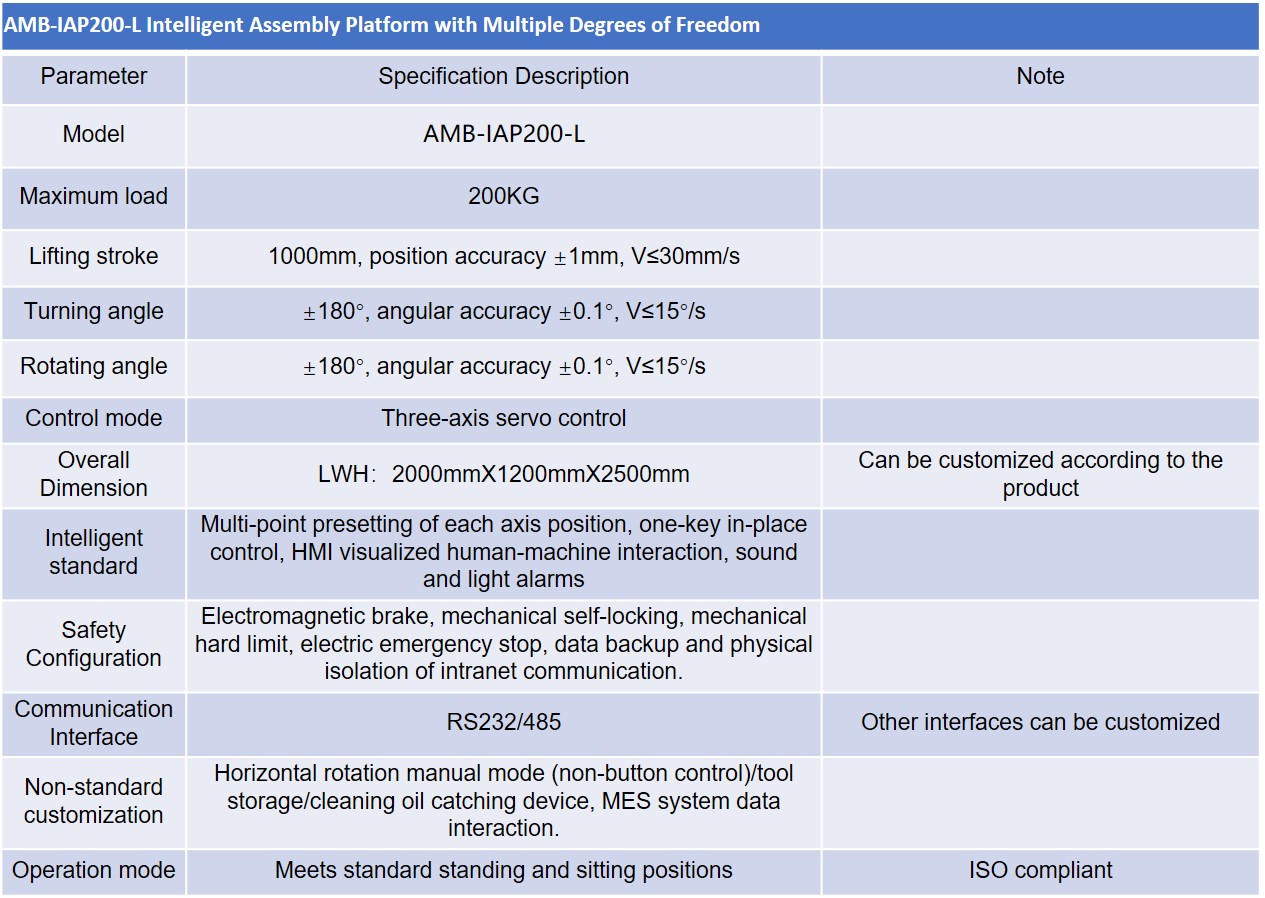

TECHNICAL PARAMETER

Aerospace industry engine parts or complete machine assembly operations,

Quality inspection,

All kinds of heavy industry parts welding positioning, attitude, suitable for robot automation operations.

Tel.

Tel.