Customer Overview:

FAW-Volkswagen Automobile Co., Ltd. is a large-scale car production enterprise jointly operated by China First Automobile Group Corporation, Volkswagen AG, Audi AG and Volkswagen (China) Investment Co., Ltd. and is China's first modernized car industrial base constructed according to the economic scale.

FAW-Volkswagen adopts advanced technology and equipment to manufacture the world famous brand products - Jetta, Bora, Golf, Kaidi and Audi series cars. Its completion has enabled China's car industry to enter a new period of mass production. The Ministry of Foreign Economic Relations and Trade recognized FAW-Volkswagen as a "technologically advanced enterprise", the National Bureau of Statistics awarded FAW-Volkswagen as a "Famous and Excellent Enterprise of China's Automobile Manufacturing", and the National Machinery Bureau awarded FAW-Volkswagen as an "Enterprise that has made great contributions to the promotion of scientific and technological progress". The State Bureau of Machinery honored FAW-Volkswagen with the first prize of "Significant Contributors in Promoting Scientific and Technological Progress".

Application Difficulties:

FAW-Volkswagen is recognized as a first-class designer and manufacturer of intelligent automotive industrial equipment, and pays great attention to human factors effectiveness in the production workshop and efficient human-machine interaction matching and environment improvement in the workplace. So they found Hai Tong Industry hoping to solve the problem of improving the environment of the welding workshop adjustment line for them.

The original equipment status of the adjustment line of FAW-VW welding workshop is as follows:

1, the front cover closure fixture tightening nuts for the left and right one, manually open the cover, holding the gun to tighten the remaining nuts left and right one, the operation is cumbersome, spends a long time; workers in the work process there are more bad posture, operational efficiency has a large space can be improved.

2、Front cover fixture and lifting mainframe leveling bracket are layered design and floating connection, the fine guide pin on the fixture is positioned in X and Y direction with the body shock absorbing holes, and the cylinder on the fixture is clamped in Z direction with the front longitudinal beam of the body. When the white body advances with the belt, the body pushes the fixture, and the fixture pushes the horizontal bracket of the lifting main body, so that the lifting main body moves to the rail in X direction. The tilting of the fixture on site is serious, which affects the accuracy of the fixture and costs more time for adjustment;

3, lifting the host handrail is now long feedback operation, easy to break, safety hazards, affecting normal production.

Customer needs and program description:

The customer expects that Hyetone Industry can provide the solution:

Improve the ergonomics environment, make the working conditions on site adapt to the production line and human needs, achieve the production beat of 52 seconds of high-frequency high-precision work, and fully reduce the labor intensity of workers, to achieve good consistency performance.

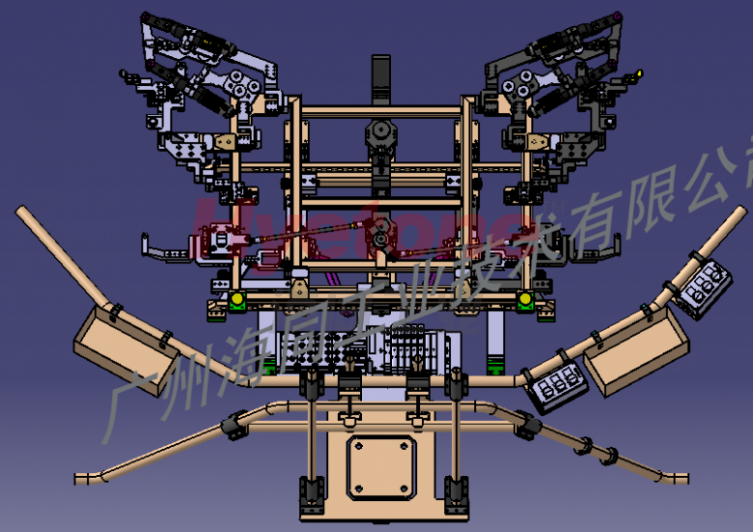

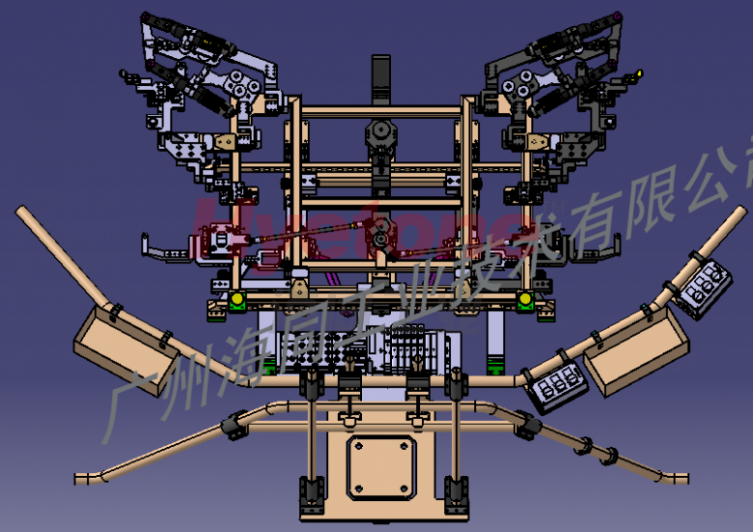

Conclusion: Hyetone industrial technical engineers after on-site mapping and inspection that through the structure of a more optimized AMB front cover closure tightening "ergonomics fixtures" can effectively improve the welding workshop adjustment line operating environment, equipment improvement and other issues to achieve increased assembly accuracy, saving operating time, adjusting the equipment to adapt to the work of the people.

Program advantages/results:

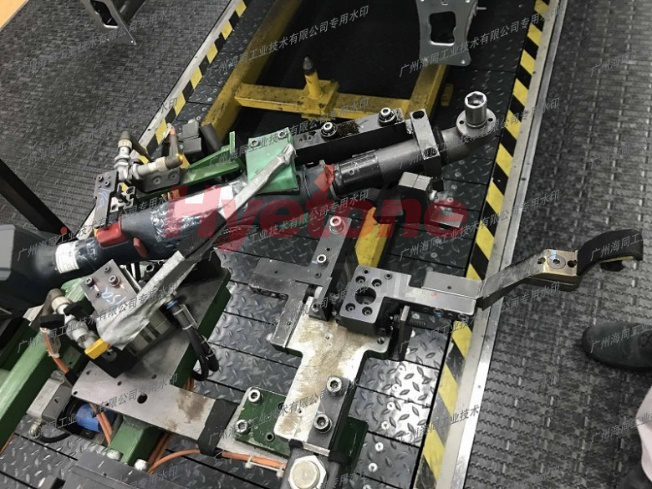

1. After opening the cover manually, the fixture can be taken out directly for the next cycle, reducing the labor intensity of manual nailing. Improve the bad posture in the original process and reduce the risk of WMSDs.

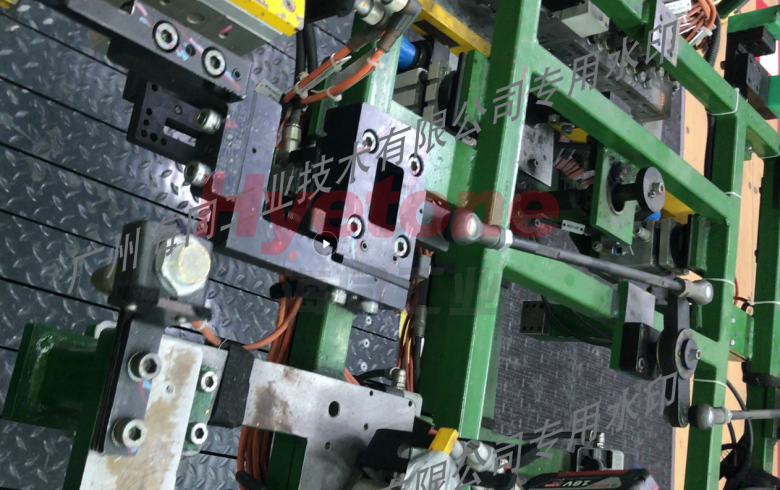

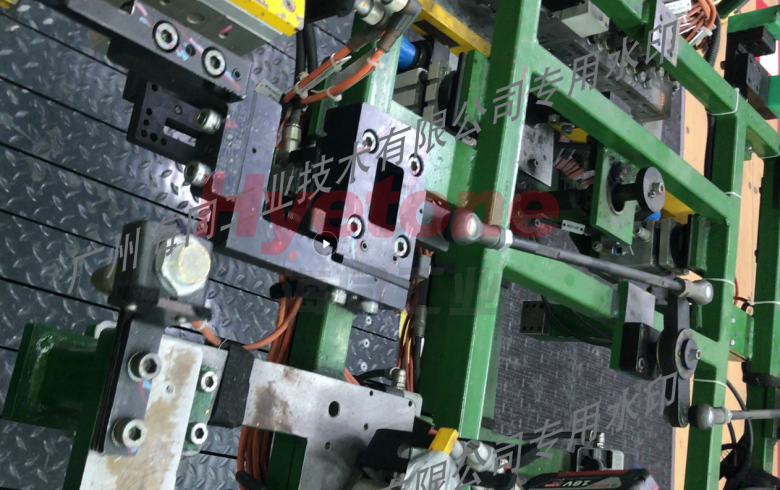

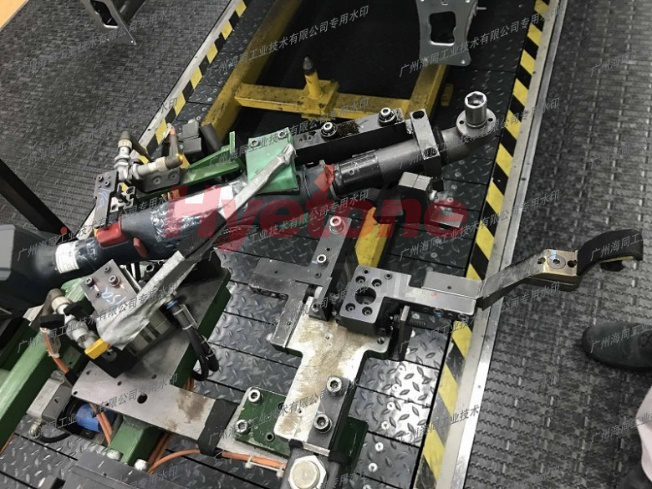

Fig. 1:AMB Front Cover Closing Automatic Tightening "Human Factors Engineering Tooling" AMB-FHD

2. The structure of the front cover fixture and the horizontal bracket of the lifting host is optimized, and the fixture is not affected by the lifting host. Installation accuracy is significantly improved; set the appropriate operating height of the equipment, and button strength, workers operate more comfortable and convenient, and the height and angle of the equipment can be adjusted to adapt to the needs of different workers to operate.

3、The handrail of the fixture is made by bending the whole round tube and increasing the reinforcement to meet the use of strength and improve the overall safety and stability of the fixture. The handrail adopts ergonomic buttons. Comprehensive consideration of ergonomic solutions to lock the working range in front of the body and a few inches above and below the elbow joint within the comfort zone.

Fig. 2: AMB Front Cover Closure Auto Tightening "Ergonomic Device" AMB-FHD2

丨Mission of Hyetone

Hyetone Industry closely links the mission of building a national innovative brand of China's industrial equipment with the destiny of the country, and continues to realize technological breakthroughs and development around the industrial concept of "Machines help human beings produce better". For the construction of socialism with Chinese characteristics in the new era, and for the realization of the Chinese dream of the great rejuvenation of the Chinese nation, we will contribute to the technology and power of human-machine interaction industrial equipment. Product contact hotline: 400-018-2086 .

Tel.

Tel.